Introduction to Custom Manufacturing in Chicago

In a bustling city like Chicago, where industries thrive and innovation is at the forefront, custom manufacturing plays a critical role. Whether you need unique parts for machinery, custom-designed products, or specialized equipment, custom manufacturing can offer solutions tailored to your specific needs. This article dives deep into the best custom manufacturing companies in Chicago, their key offerings, and how you can benefit from their expertise.

Table of Contents

What Is Custom Manufacturing?

Custom manufacturing is the process of creating products or components that are specifically designed to meet the unique requirements of a customer or project. Unlike mass production, which focuses on producing large volumes of identical products, custom manufacturing offers flexibility, allowing businesses to tailor every aspect of a product, from its design to its materials, size, and functionality. This personalized approach is crucial when standard, off-the-shelf items aren’t sufficient.

Custom manufacturing can range from producing small batches of specialized parts to crafting one-off prototypes. It often involves close collaboration between the client and the manufacturer to ensure that the final product meets precise specifications.

Advantages of Custom Manufacturing

Custom manufacturing offers several key benefits over mass production, particularly for businesses that need specialized solutions.

1. Tailored to Specific Needs

Custom manufacturing allows for the creation of products that precisely fit the needs of a project or client. Whether it’s a machine part with exact dimensions or a product with unique functionality, custom manufacturing ensures that every detail is fine-tuned.

2. Greater Flexibility

One of the biggest advantages of custom manufacturing is its flexibility. Clients can modify designs, change materials, or tweak features throughout the process. This adaptability allows for greater innovation and problem-solving during product development.

3. Prototyping and Small Batch Production

Custom manufacturing is ideal for companies that need to create a prototype or produce limited quantities. Rather than committing to large-scale production, businesses can test and refine a product on a smaller scale, reducing costs and risks.

4. Higher Quality and Precision

With custom manufacturing, each product is crafted to meet specific standards, often resulting in higher quality and precision. The focus is on ensuring that each item functions perfectly within its intended use, rather than meeting generic requirements.

Examples of Custom Manufacturing

Custom manufacturing is widely used across many industries where precision and specialized products are essential. Here are some common examples:

- Aerospace: Custom parts for aircraft, such as engine components or landing gear, which need to meet exact safety and performance standards.

- Automotive: Customized car parts, especially for high-performance or luxury vehicles, where unique features and materials are often required.

- Healthcare: Medical devices and equipment, like implants or prosthetics, that need to fit a patient’s body perfectly.

- Electronics: Custom circuit boards or specialized hardware components designed for unique tech applications.

- Construction: Custom building materials or structural components designed for specific architectural needs.

Why Choose Custom Manufacturing?

Custom manufacturing is all about creating products that fit your exact specifications, rather than relying on mass-produced, one-size-fits-all solutions. But why should you opt for custom manufacturing over traditional manufacturing methods?

Benefits of Custom Manufacturing Over Traditional Manufacturing

When you’re looking for precision, uniqueness, and quality, custom manufacturing stands out. Here’s why:

Flexibility in Design and Production

One of the biggest advantages of custom manufacturing is its flexibility. Traditional manufacturers often have rigid processes, which makes it hard to deviate from standard designs. With custom manufacturing, you can tweak everything from materials to dimensions.

Tailoring Solutions to Business Needs

Whether you’re in aerospace, automotive, healthcare, or any other industry, custom manufacturers work closely with you to develop tailored solutions. They ensure the product is just right for your specific business requirements, down to the last detail.

Speed and Agility in Custom Production

Time is money in business, and custom manufacturing understands that. They are typically more agile and faster at delivering prototypes or final products compared to large, traditional manufacturers that might have long production schedules.

Competitive Edge Through Customization

In today’s competitive market, customization can set you apart from competitors. Offering bespoke products can help attract new clients, retain old ones, and position your business as a leader in innovation.

When to Use Best Custom Manufacturing

Custom manufacturing is an invaluable solution when off-the-shelf products just won’t cut it. Whether you’re designing something entirely new or modifying an existing product, custom manufacturing provides the flexibility, precision, and creativity you need. Below are the key scenarios where custom manufacturing is the ideal choice.

1. When You Need a Unique Design

Custom manufacturing is perfect when your product or part requires a design that is not available in the market. If you have unique specifications, dimensions, or functions that don’t fit within standard manufacturing processes, custom manufacturing lets you create the exact product you need.

Example:

An aerospace company might need a metal part designed to handle extreme heat and stress that isn’t available in standard catalogs. Custom manufacturing can design and produce this exact component.

2. When Precision Is Critical

In industries like healthcare, automotive, and electronics, precision can be the difference between success and failure. Custom manufacturing ensures that each part or product is made to exact specifications, delivering greater accuracy than mass-produced alternatives.

Example:

In the medical field, implants or prosthetics must be created to exact measurements to fit a patient perfectly. Custom manufacturing allows for this level of precision.

3. When You Need Prototyping or Small Batches

Developing a new product often requires testing prototypes or producing small batches for evaluation before scaling up production. Custom manufacturing is ideal for creating these prototypes, allowing for design improvements and iterations without the need for mass production.

Example:

A tech startup creating a new gadget might need several prototype versions to test functionality before finalizing the design. Custom manufacturing can produce these prototypes quickly for testing.

4. When You Require Specialized Materials

Sometimes, your project requires materials that aren’t commonly used in mass production. Whether it’s high-durability alloys, heat-resistant composites, or flexible plastics, custom manufacturing allows you to choose the perfect materials for your product’s needs.

Example:

An automotive manufacturer might require a lightweight, high-strength material for vehicle parts to improve fuel efficiency. Custom manufacturing makes it possible to select and use materials that meet those specific requirements.

5. When You Need to Retrofit or Upgrade Existing Systems

If you’re upgrading or repairing existing equipment, finding the right parts can be challenging. Custom manufacturing lets you design components that fit perfectly with your current system, preventing the need for costly replacements of entire machines.

Example:

A manufacturing plant with aging machinery might need a specific custom part that is no longer produced. Instead of replacing the entire machine, custom manufacturing can create the necessary part to keep operations running.

6. When You Want a Competitive Advantage

In a crowded market, offering custom products can help differentiate your business from competitors. Custom manufacturing enables you to provide unique products tailored to specific customer needs, which can set you apart from others in your industry.

Example:

A high-end furniture company might use custom manufacturing to produce bespoke pieces for luxury clients, giving them an edge over mass-produced furniture options.

7. When Speed and Flexibility Are Priorities

When you’re working with tight deadlines or need the ability to modify designs during production, custom manufacturing is the way to go. It offers more agility than mass production, allowing you to make changes or produce items quickly to meet urgent demands.

Example:

A company developing emergency response tools might need to create new equipment rapidly in response to a natural disaster. Custom manufacturers can step in and deliver quick prototypes and small production runs in a short timeframe.

8. When You’re Dealing With Highly Regulated Industries

Industries like aerospace, defense, and medical devices are governed by strict regulations, and mass-produced products might not meet these specific standards. Custom manufacturing ensures that each item is designed and built to comply with these regulatory requirements.

Example:

In the defense industry, custom manufacturers might need to develop specialized parts for military vehicles that adhere to exacting standards and performance requirements.

How Custom Manufacturing Works

In custom manufacturing, businesses work closely with manufacturers to design and produce a product or part that isn’t readily available off-the-shelf. This process can involve:

- Designing: Starting from a concept or modifying an existing design.

- Prototyping: Creating a sample or prototype to ensure the design meets the customer’s needs.

- Production: Once approved, moving to full production, whether it’s a small batch or large-scale production run.

Each step is highly flexible, allowing changes to the design, materials, or production techniques based on feedback and performance.

Key Features of Custom Manufacturing

Bespoke Production

The hallmark of custom manufacturing is the creation of products specifically designed for the client’s needs. Whether it’s an unusual size, a different material, or a unique function, everything about the product is customized to exact specifications.

Small to Large Scale

Custom manufacturing isn’t limited to just one-off products. While it can involve creating a single prototype or small batch, many custom manufacturers also offer large-scale production once the design is finalized and perfected.

Specialized Solutions

For businesses that require unique components or products that can’t be found in the market, custom manufacturing offers solutions. Whether it’s a highly technical part or a specially designed product for a niche market, the focus is on providing exactly what the customer needs.

Flexibility

One of the biggest advantages of custom manufacturing is flexibility. Changes can be made during the design or production phase, ensuring the final product is precisely what the client envisioned. This adaptability allows for ongoing improvements and tweaks to ensure the product performs well in real-world applications.

Examples of Custom Manufacturing

Custom manufacturing is used across many industries where precision and specialized products are necessary. Here are some common examples:

Metal Fabrication

In industries like construction, automotive, and aerospace, custom metal fabrication is vital. Manufacturers create specific parts or components from metals like aluminum, steel, or copper that meet exact dimensions and quality standards.

Plastic Molding

Custom plastic injection molding is widely used to create components for electronics, medical devices, and consumer goods. Businesses can specify the type of plastic, shape, and size needed for their product.

Custom Electronics

Many industries require custom-made electronics like circuit boards or specialized wiring systems. In the tech and telecommunications sectors, custom manufacturing helps create products that fit unique designs or performance requirements.

Top Custom Manufacturing Sectors in Chicago

Chicago has long been a hub for various industries, and the custom manufacturing sector is no different. Let’s take a look at the top industries driving demand for custom manufacturing in the Windy City.

Metal Fabrication

Metal fabrication remains a stronghold in Chicago’s manufacturing industry. Custom metal fabrication services offer solutions for industries like construction, automotive, and heavy machinery. Whether it’s stainless steel, aluminum, or copper, custom manufacturers in Chicago have the tools and expertise to craft precise metal components.

Plastic Injection Molding

Custom plastic injection molding is another key sector. From small parts used in consumer electronics to large automotive components, Chicago-based companies excel in producing high-quality, custom-molded plastic parts for a wide range of industries.

Electronics and Technology Manufacturing

In our tech-driven world, custom electronics manufacturing is booming in Chicago. From specialized circuit boards to custom wiring harnesses, the city’s manufacturers serve industries like telecommunications, defense, and consumer electronics, providing cutting-edge solutions for unique electronic needs.

Criteria for Choosing the Best Custom Manufacturing Company

So, how do you choose the right custom manufacturing company in Chicago? Here are a few key factors to keep in mind:

Quality of Products

Quality should always be at the top of your list when selecting a manufacturer. You want products that meet your specifications and perform well under real-world conditions.

Adherence to Industry Standards

A good custom manufacturer will ensure their products adhere to the highest industry standards. Certifications like ISO, AS9100, or IATF are indicators of quality and consistency in manufacturing processes.

Use of Advanced Technology

The best custom manufacturers invest in advanced technologies like 3D printing, CNC machining, and robotics to ensure precision, efficiency, and innovation in their products.

Turnaround Time and Delivery

In today’s fast-paced business world, timely delivery is crucial. Choose a manufacturer known for meeting deadlines without compromising on quality.

Cost-Effectiveness

While custom manufacturing often comes with a premium, it doesn’t mean you should break the bank. A good manufacturer will provide cost-effective solutions, balancing quality, speed, and affordability.

Spotlight on the Best Custom Manufacturing Company in Chicago

Let’s highlight one of the top custom manufacturing companies in Chicago that consistently delivers excellence in every aspect of its operations.

Overview of the Company

This Chicago-based custom manufacturing company has been serving businesses across the US for over 20 years. Known for its expertise in metal fabrication, plastic injection molding, and electronics manufacturing, the company offers a one-stop shop for all your custom manufacturing needs.

Services Offered by the Company

From concept to completion, this company provides a wide range of services to support businesses across industries.

Prototyping Services

Need to test a new product design? The company’s prototyping services allow businesses to create working models quickly, ensuring the design functions as expected before going into full production.

Full-Scale Manufacturing

Once the prototype is perfected, the company offers full-scale manufacturing services, ensuring large orders are handled with precision and care.

Custom Design and Engineering Solutions

Their in-house team of engineers works closely with clients to develop custom designs, ensuring that every component fits the project’s unique requirements.

What Makes This Company Stand Out?

What sets this company apart is its commitment to innovation, quality, and customer satisfaction. With a track record of delivering on time and a strong focus on advanced technologies like CNC machining and 3D printing, they consistently outperform competitors.

Customer Testimonials and Success Stories

Positive Client Feedback

Clients rave about the company’s exceptional service, quick turnaround times, and commitment to quality. Many highlight the personalized attention and the willingness to go the extra mile to meet deadlines.

Case Studies of Successful Projects

One notable success story involves a partnership with a major automotive manufacturer. The custom manufacturing company developed a complex metal part that improved engine efficiency, helping the client reduce emissions and win a significant government contract.

How to Find the Best Custom Manufacturer

Finding the best custom manufacturer for your specific needs can be a challenging yet crucial task. Whether you’re looking for a local provider or an international supplier, knowing where to search and how to evaluate potential manufacturers is essential. Below, we’ll explore effective strategies to help you discover the right custom manufacturer for your projects.

1. Online Manufacturing Platforms

One of the easiest ways to find custom manufacturers is through online platforms that connect businesses with a vast network of suppliers. These platforms provide access to thousands of manufacturers, complete with reviews, ratings, and detailed profiles.

Popular Platforms to Explore:

- ThomasNet: Often referred to as the “yellow pages” for manufacturers, ThomasNet lists thousands of verified suppliers, including custom manufacturing companies, along with detailed company profiles.

- Maker’s Row: This platform specializes in connecting businesses with American manufacturers, offering custom solutions for various industries such as apparel, furniture, and electronics.

- Xometry: Xometry provides instant quotes for custom manufacturing jobs and connects you with vetted manufacturers specializing in CNC machining, 3D printing, and injection molding.

2. Trade Shows and Industry Expos

Attending trade shows is an excellent opportunity to meet manufacturers face-to-face and see their work firsthand. Many industries host annual trade shows that bring together the best manufacturers from around the world.

Why Attend Trade Shows?

- Networking Opportunities: You can speak directly with manufacturers, ask questions, and get a feel for their operations.

- Hands-On Demos: Many manufacturers showcase their capabilities by providing product samples and machine demonstrations.

- Industry-Specific Focus: You can attend trade shows tailored to your industry, ensuring that the manufacturers you meet are relevant to your business needs.

3. Local Directories and Listings

If you prefer working with a manufacturer in your area, local directories and business listings are a great place to start. Websites like Google My Business and Yelp allow you to search for custom manufacturers nearby and often feature reviews from previous clients.

How to Use Local Directories:

- Search for Custom Manufacturers: Simply input your location and search for custom manufacturers in your city or state.

- Read Reviews: Customer reviews provide insights into the quality of work, customer service, and reliability of each manufacturer.

4. Industry Associations and Certifications

Look for custom manufacturers that are members of industry associations or have specialized certifications. These groups often maintain directories of vetted and certified manufacturers, ensuring you find a reliable provider.

Examples of Associations and Certifications:

- ISO Certifications: Manufacturers with ISO certifications follow strict quality control standards, making them a safer choice for custom manufacturing.

- National Association of Manufacturers (NAM): NAM is one of the largest manufacturing associations in the U.S. and offers a directory of its members.

- Custom Manufacturer & Fabricator Associations: Many industries have specific associations dedicated to custom manufacturing, such as the Precision Metalforming Association (PMA) or the American Mold Builders Association (AMBA).

5. Referrals and Word of Mouth

Sometimes, the best way to find a reliable custom manufacturer is through referrals. Ask colleagues, industry peers, or other businesses who they’ve worked with and what their experience was like.

Why Referrals Work:

- Trustworthy Recommendations: Referrals are based on firsthand experiences, so you’re more likely to find a manufacturer you can trust.

- Detailed Feedback: Those who have worked with a manufacturer can give you specific details on what to expect, including turnaround times, communication, and quality of work.

6. Manufacturer Websites

Many custom manufacturers have detailed websites showcasing their capabilities, industries served, and past projects. These sites often include case studies, customer testimonials, and photos of their facilities and products.

What to Look For:

- Portfolio: Review their past work to see if it aligns with your needs.

- Capabilities: Ensure the manufacturer has the equipment and expertise to handle your specific project.

- Testimonials: Reviews from other clients can give you an idea of the manufacturer’s reliability and quality of service.

7. Outsourcing Agencies

If you’re unsure where to start, consider working with outsourcing agencies that specialize in connecting businesses with custom manufacturers. These agencies typically have established relationships with manufacturers and can match you with the best provider based on your needs.

Benefits of Using an Agency:

- Expert Guidance: Agencies often have experience with various manufacturers and can guide you to the best fit for your project.

- Time Savings: Instead of searching on your own, the agency can do the legwork for you, making the process quicker and more efficient.

8. Global Sourcing Platforms

If you’re open to working with international manufacturers, global sourcing platforms like Alibaba or Global Sources offer access to manufacturers from around the world. These platforms can be especially useful for large-scale production or industries requiring specific materials or techniques.

Why Use Global Sourcing Platforms:

- Diverse Options: You can find manufacturers that specialize in nearly every type of product and material.

- Competitive Pricing: International manufacturers may offer competitive pricing, especially for bulk orders.

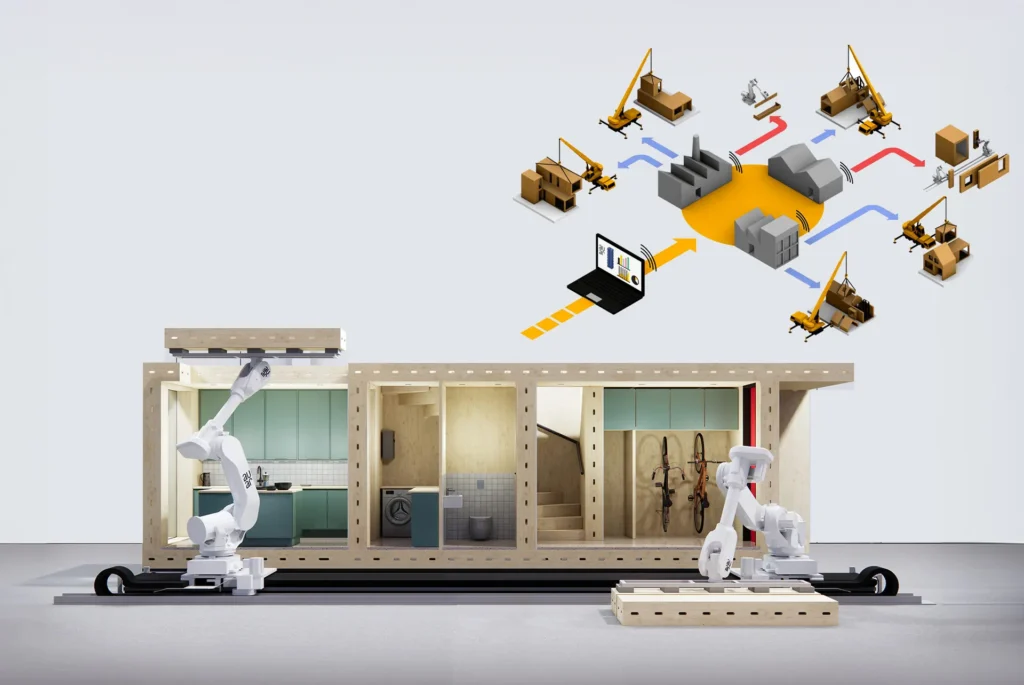

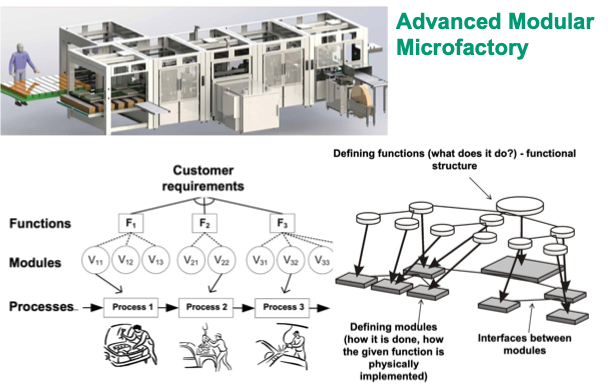

Effective Ways Microfactory Became the Best Custom Manufacturer

Mikrofactory’s rise to becoming the best custom manufacturer didn’t happen overnight. It was the result of adopting effective strategies, using cutting-edge technology, and consistently delivering high-quality, tailored solutions to its clients. Below are some of the most effective ways that Mikrofactory became a leader in the custom manufacturing industry.

1. Prioritizing Client Collaboration

Mikrofactory understands that no two clients are the same, which is why they prioritize close collaboration with each customer from the very start. This personalized approach ensures that they fully understand the client’s needs, goals, and vision, leading to a more successful outcome.

How They Do It:

- Tailored Consultations: Mikrofactory takes the time to learn about each client’s specific challenges and opportunities before offering a custom solution.

- Continuous Communication: Throughout the project, Mikrofactory maintains open channels of communication, keeping clients updated and involved in every step.

2. Leveraging Cutting-Edge Technology

To stay ahead in the custom manufacturing industry, Mikrofactory continually invests in the latest technology. From 3D printing to CNC machining and laser cutting, their use of advanced tools ensures precision, speed, and innovation in every project.

Technology in Action:

- 3D Printing: This enables rapid prototyping, allowing clients to see and test a model before full production.

- CNC Machining: With computer-controlled tools, Mikrofactory can create highly precise components for industries that require exact tolerances, such as aerospace and healthcare.

3. Focusing on Flexibility and Customization

Customization is at the core of what Mikrofactory does. By providing flexible manufacturing solutions, they ensure that no matter the size, complexity, or industry, clients receive products that are specifically designed to meet their unique requirements.

Get your best custom manufacture at affordable now[1]

Why Flexibility Matters:

- Adaptable Production: Whether it’s a small prototype or a large production run, Mikrofactory scales production to match the client’s needs.

- Material Versatility: They offer a wide variety of materials, from metals and plastics to high-performance composites, ensuring that the final product is perfect for its intended use.

4. Rapid Prototyping for Faster Results

One of Mikrofactory’s most effective strategies has been their rapid prototyping services. By creating prototypes quickly and efficiently, clients can test designs early in the process, saving time and reducing the risk of costly errors.

How Rapid Prototyping Helps:

- Design Validation: Clients can test the functionality and aesthetics of their designs before committing to full-scale production.

- Speed to Market: By using fast prototyping techniques, Mikrofactory helps clients bring their products to market more quickly, which is crucial in fast-paced industries like tech and electronics.

5. Assembling a Team of Experts

Behind Mikrofactory’s success is a team of experienced engineers, designers, and technicians who bring extensive knowledge and expertise to every project. Their team thrives on solving complex problems and pushing the boundaries of what custom manufacturing can achieve.

Team Expertise in Action:

- Collaborative Problem Solving: The team works closely with clients to overcome technical challenges and deliver innovative solutions that meet strict industry standards.

- Continuous Training: Mikrofactory invests in ongoing education and training for their staff, keeping them at the cutting edge of manufacturing trends and techniques.

6. Implementing Rigorous Quality Control

For Mikrofactory, quality is non-negotiable. They’ve implemented strict quality control measures at every stage of production, ensuring that each product meets the highest standards. This attention to detail has earned them a reputation for reliability and excellence.

Quality Control Process:

- In-Depth Inspections: Every product undergoes rigorous inspection during and after production to ensure it meets all specifications.

- High-Quality Materials: Mikrofactory only uses premium materials, ensuring that every product is durable, reliable, and fits the client’s needs perfectly.

7. Offering Scalable Solutions for Any Industry

Whether a company needs a single custom prototype or thousands of parts, Mikrofactory’s scalable production process can accommodate any order size. This versatility has allowed them to serve a wide range of industries, from aerospace to healthcare to consumer goods.

Scalability in Action:

- Small Batch or Mass Production: Mikrofactory’s flexible operations allow them to efficiently manage both small-batch custom orders and large-scale production runs.

- Industry-Specific Solutions: With extensive experience across multiple sectors, they understand the unique needs of industries like automotive, electronics, and medical devices, ensuring that products meet industry standards and regulations.

8. Fostering Innovation and Creativity

Innovation is a key driver for Mikrofactory, allowing them to push the limits of what’s possible in custom manufacturing. By continuously experimenting with new materials, processes, and designs, Mikrofactory delivers cutting-edge solutions that keep clients ahead of the curve.

Examples of Innovation:

- Material Innovation: Mikrofactory stays ahead by adopting the latest materials, such as high-strength alloys and biodegradable plastics, to create products that are both functional and sustainable.

- Process Innovation: They are always exploring ways to make production more efficient, whether through automation, advanced manufacturing techniques, or eco-friendly processes.

9. Delivering Outstanding Customer Service

At Mikrofactory, the client’s experience is just as important as the final product. They pride themselves on providing outstanding customer service, from the initial consultation through to after-sales support. This ensures that clients not only get a product that meets their needs but also enjoy a smooth, transparent process.

Key Customer Service Strategies:

- Clear Communication: Clients receive regular updates and are kept informed throughout the entire project.

- Ongoing Support: Even after a project is completed, Mikrofactory continues to offer support and troubleshooting to ensure complete satisfaction.

10. Commitment to Sustainability

In today’s manufacturing landscape, sustainability is more important than ever. Mikrofactory is committed to using eco-friendly materials and energy-efficient processes to reduce their environmental footprint without sacrificing product quality.

Sustainability Efforts:

- Recyclable Materials: Whenever possible, Mikrofactory uses recyclable or sustainable materials in production.

- Energy-Efficient Equipment: They utilize state-of-the-art machinery that minimizes energy consumption and reduces waste.

Becoming the Best Custom Manufacturing Company: Microfactory’s Journey

In a world where businesses and industries are constantly evolving, custom manufacturing has become the go-to solution for companies seeking specialized products that meet exact specifications. For Mikrofactory, becoming the best custom manufacturing company has been a journey marked by innovation, customer-focused solutions, and cutting-edge technology. Here’s how Mikrofactory set itself apart in the highly competitive landscape of custom manufacturing.

1. Embracing Customization for Every Client

At the heart of Mikrofactory’s success is its dedication to true customization. Unlike mass manufacturers that churn out standard products, Mikrofactory focuses on understanding each client’s unique needs, offering tailored solutions for every project. Whether it’s a small prototype or a large-scale production run, Mikrofactory ensures that every detail is perfected to meet client specifications.

What Sets Mikrofactory Apart?

- Client-Centered Approach: Mikrofactory takes the time to collaborate with clients, understanding their vision and goals to create products that fit their exact requirements.

- Bespoke Solutions: From the design phase to production, everything is built around the client’s needs, ensuring a perfect fit every time.

2. Cutting-Edge Technology and Equipment

To be the best in custom manufacturing, you need access to the best tools and technology. Mikrofactory invests heavily in advanced manufacturing equipment, utilizing the latest in CNC machining, 3D printing, and laser cutting technologies. This allows the company to offer unparalleled precision and flexibility across a range of industries, including aerospace, automotive, healthcare, and electronics.

Why Technology Matters

- Increased Precision: Advanced tools and technology ensure that every product is made with exact specifications, leaving no room for error.

- Faster Turnaround: The use of automated machines and innovative software allows for quicker production times without sacrificing quality.

3. Skilled Team of Experts

Mikrofactory owes much of its success to its team of highly skilled engineers, designers, and technicians. With years of experience and a passion for problem-solving, Mikrofactory’s team can take on the most complex manufacturing challenges. Their expertise ensures that even the most demanding projects are completed on time and to the highest quality standards.

The Role of Expertise in Custom Manufacturing

- Innovative Problem Solving: The team thrives on complex projects, where creativity and technical knowledge are key to finding solutions that standard manufacturers can’t offer.

- Continuous Learning: Mikrofactory’s team stays updated on the latest trends and techniques, ensuring they’re always at the forefront of the industry.

4. Commitment to Quality and Precision

In custom manufacturing, precision and quality are non-negotiable. Mikrofactory has built a reputation for delivering products that meet the highest standards. From the materials used to the final inspection, every step of the process is designed to ensure flawless execution.

How Mikrofactory Guarantees Quality

- Strict Quality Control: Each product undergoes rigorous quality control checks, from design to production to final delivery.

- High-Quality Materials: Mikrofactory only uses the best materials available, ensuring that every product is durable, reliable, and built to last.

5. Flexibility and Scalability

One of the hallmarks of a great custom manufacturing company is its ability to handle projects of all sizes. Mikrofactory has mastered the art of flexibility, offering solutions for both small, one-off prototypes and large-scale production runs. This scalability has made it a trusted partner for businesses across various industries, from startups to established enterprises.

Why Flexibility Matters

- Adaptability: Whether a client needs a small batch or thousands of units, Mikrofactory can scale production to meet demand without compromising on quality.

- Quick Adjustments: Custom projects often require changes along the way. Mikrofactory’s flexible production process allows for real-time adjustments based on client feedback.

6. Prototyping and Innovation

For companies that are innovating new products, rapid prototyping is essential. Mikrofactory has perfected the art of quick, cost-effective prototyping, allowing clients to test and refine their designs before committing to full-scale production. This ability to create and modify prototypes quickly gives clients the confidence that their final product will perform as expected.

Benefits of Rapid Prototyping at Mikrofactory

- Cost-Efficiency: Creating prototypes allows clients to fine-tune their designs before large production runs, saving costs and reducing risks.

- Speed to Market: Prototypes are produced quickly, allowing businesses to get their products to market faster than their competitors.

7. Industry-Specific Expertise

Mikrofactory’s custom manufacturing solutions span a wide range of industries, giving the company deep insight into each sector’s specific needs. Whether it’s creating precision parts for the aerospace industry or developing custom tools for medical devices, Mikrofactory has the expertise and knowledge to cater to highly regulated and specialized markets.

Industries Served

- Aerospace: Precision parts designed to withstand extreme conditions.

- Automotive: Custom components for performance and luxury vehicles.

- Healthcare: Medical devices and tools designed for patient-specific needs.

- Electronics: Custom circuit boards and electronic components for specialized tech.

8. Outstanding Customer Service

Mikrofactory’s commitment to excellent customer service has been a key factor in its growth and success. From initial consultation to final delivery, the company ensures that clients are kept informed every step of the way. This transparency builds trust and fosters long-term relationships with clients.

Customer Service Excellence

- Open Communication: Clients are kept in the loop throughout the entire process, with regular updates and clear timelines.

- After-Sales Support: Even after the project is completed, Mikrofactory offers ongoing support to ensure complete customer satisfaction.

9. Sustainability and Innovation

Mikrofactory is dedicated to sustainable practices and incorporates environmentally friendly materials and production methods whenever possible. The company recognizes the growing importance of eco-friendly solutions in manufacturing and strives to minimize its environmental impact while maintaining high-quality standards.

Sustainable Manufacturing

- Eco-Friendly Materials: Where possible, Mikrofactory uses sustainable or recyclable materials in production.

- Energy-Efficient Processes: By using state-of-the-art equipment, Mikrofactory reduces energy consumption and waste during manufacturing.

Conclusion

If you’re looking for a reliable custom manufacturing company in Chicago, you’re in the right place. Chicago is home to some of the best custom manufacturers in the US, offering a combination of expertise, advanced technology, and customer-focused service. The highlighted company stands out for its commitment to innovation, quality, and customer satisfaction—ensuring your project, whether big or small, is completed to the highest standards.

FAQs About Custom Manufacturing in Chicago

- What industries benefit most from custom manufacturing?

- Custom manufacturing is versatile and serves industries like automotive, aerospace, healthcare, electronics, and construction.

- How long does the custom manufacturing process typically take?

Timelines vary depending on the complexity of the project, but prototyping can be done in a few weeks, while full production may take several months. - Is custom manufacturing more expensive than traditional manufacturing?

Custom manufacturing can be more expensive, especially for small batches, but the tailored solutions and high quality often outweigh the cost. - Can custom manufacturers handle large production runs?

Yes, many custom manufacturers offer both small-batch prototyping and large-scale production capabilities. - How can I ensure my custom manufacturing project stays within budget?

Work closely with your manufacturer to clarify your budget early on and prioritize features and materials that align with cost constraints.