Best 3D Printing Chicago isn’t just the Windy City; it’s also a bustling hub for innovation, especially in Best 3D Printing . Whether you’re a startup looking to prototype your next big idea or a large manufacturer needing high-quality parts, the city has a plethora of options. In this article, we’ll dive into the best 3D printing manufacturers in Chicago, explore why the city is perfect for this industry, and give you some tips on choosing the right manufacturer for your needs.

Table of Contents

Understanding Best 3D Printing

What is 3D Printing?

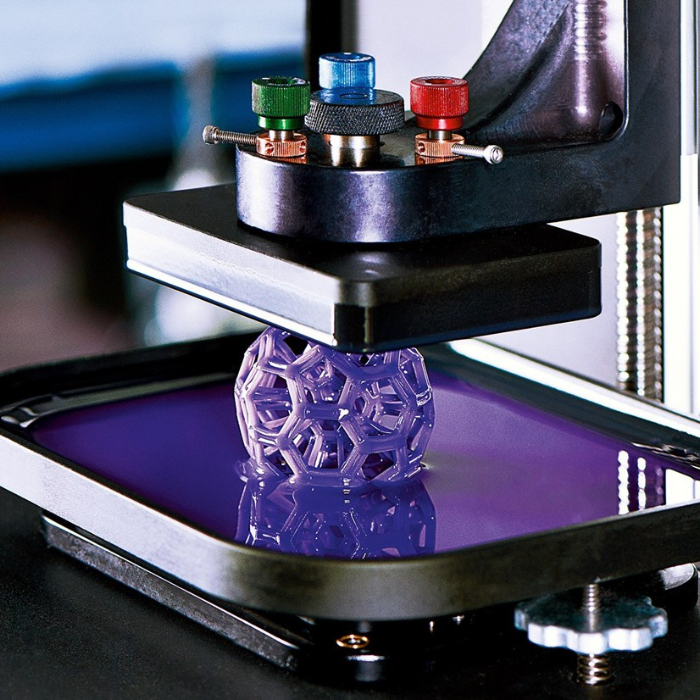

3D printing, or additive manufacturing, is the process of creating three-dimensional objects from a digital file. Layers of material are built up to form the final product, which can range from prototypes to end-use parts. This technology has revolutionized how products are designed and manufactured, making it easier and faster than ever to bring ideas to life.

Importance of 3D Printing in Manufacturing

The significance of Best 3D Printing in the manufacturing sector cannot be overstated. It allows for rapid prototyping, which speeds up the development process. Businesses can quickly iterate designs, test functionality, and make adjustments—all before committing to mass production. This agility not only saves time but also cuts costs and reduces waste.

Why Chicago is a Hub for Best 3D Printing

The Growing Tech Scene

Chicago’s tech scene is booming, with many startups and established companies exploring innovative technologies, including 3D printing. This surge creates a robust ecosystem where collaboration and knowledge-sharing thrive, benefiting businesses and manufacturers alike.

Availability of Skilled Labor

The city is home to numerous educational institutions, producing a steady stream of talented graduates specializing in engineering, design, and manufacturing. This skilled labor force is vital for companies in the 3D printing industry, ensuring they have the expertise needed to stay competitive.

Educational Institutions

Schools like the Illinois Institute of Technology and the University of Illinois at Chicago offer programs focusing on 3D printing technology, ensuring that the workforce remains skilled and up-to-date with the latest advancements.

How to Choose the Right 3D Printing Manufacturer

Assessing Your Project Needs

Before selecting a manufacturer, it’s essential to assess your project requirements. Consider factors such as material needs, production volume, and design complexity.

Evaluating Manufacturer Credentials

Look into the manufacturer’s experience, technology, and customer reviews. It’s crucial to choose a manufacturer that aligns with your project’s specific needs and can deliver quality results.

Why we use 3D Printing

We use 3D printing because it offers a range of benefits that traditional manufacturing methods can’t match. Here are some key reasons why 3D printing has become so popular across various industries:

1. Rapid Prototyping

3D printing allows businesses and designers to quickly create prototypes and mock-ups of their designs. Instead of waiting weeks for a prototype to be machined or molded, 3D printing can produce it in a matter of hours or days. This speeds up the design and development process, enabling faster innovation and testing.

2. Customization

With 3D printing, products can be fully customized to meet specific requirements or individual preferences. This is especially useful in industries like healthcare, where custom medical implants, prosthetics, or dental devices are made to fit individual patients perfectly. It’s also valuable in consumer products, offering unique, one-of-a-kind items.

3. Cost Efficiency for Small Production Runs

For small-batch production or one-off items, Best 3D Printing is much more cost-effective than traditional manufacturing. There’s no need for expensive molds, tooling, or setup costs. You can print exactly what you need, when you need it, without the expense of mass production.

4. Design Freedom and Complexity

3D printing enables complex designs that would be impossible or highly expensive to achieve with conventional manufacturing techniques. Intricate geometries, overhangs, and hollow structures can be printed easily, allowing designers to push the boundaries of creativity and functionality.

5. Reduced Waste

Traditional manufacturing methods, like CNC machining, often involve cutting away material, which leads to waste. In contrast, 3D printing is an additive process, meaning material is added only where it’s needed. This significantly reduces material waste, making it a more environmentally friendly option.

6. Shorter Time to Market

Because 3D printing allows for rapid production and iterative design, companies can bring products to market much faster. Iterations can be printed, tested, and improved upon in days rather than weeks, which is crucial in competitive industries like tech and consumer goods.

7. On-Demand Manufacturing

3D printing enables on-demand production, meaning you can print parts or products as needed, reducing the need for inventory and warehousing. This is a huge advantage for industries like automotive, where spare parts can be printed when required instead of being stocked for years.

8. Localized Production

With 3D printing, manufacturing can happen closer to the end-user. Instead of outsourcing production overseas, businesses can set up local Best 3D Printing facilities, reducing shipping costs, lead times, and carbon footprints.

9. Versatility in Materials

3D printing works with a wide range of materials, including plastics, metals, ceramics, and even biological substances. This versatility opens up endless possibilities for creating anything from durable industrial parts to delicate art pieces.

10. Innovation in Healthcare and Education

In healthcare, 3D printing is revolutionizing areas like prosthetics, surgical planning, and bioprinting. In education, it helps students and professionals alike to visualize complex models and understand practical applications of theoretical concepts.

Summary: Why Use 3D Printing?

We use 3D printing because it offers speed, flexibility, customization, and cost-efficiency for everything from prototyping to large-scale production. Whether it’s designing intricate products or creating tailored medical solutions, 3D printing allows for innovation without the high costs and time constraints of traditional manufacturing.

When we can use 3D Printing

3D printing can be used in a wide variety of situations and applications, especially when traditional manufacturing methods may not be as efficient or feasible. Here are several common scenarios where 3D printing is particularly useful:

1. Prototyping and Product Development

One of the most common uses for 3D printing is in the early stages of product development. If you need to create a physical model to test form, fit, or function, 3D printing allows you to rapidly produce a prototype.

- When to use: You need a fast, cost-effective way to create and test a design or idea before committing to large-scale production.

- Why: It allows quick iteration and adjustments without the need for expensive molds or tooling.

2. Custom and Personalized Products

3D printing shines when creating one-off or highly customized items. If you need a part or product tailored to specific measurements or preferences, 3D printing allows for that level of precision.

- When to use: For personalized products like custom-fit medical devices (e.g., prosthetics, orthotics), dental implants, or bespoke consumer goods (e.g., customized jewelry, fashion accessories).

- Why: Traditional methods may not easily support individualized designs, while 3D printing handles customization efficiently.

3. Low-Volume Production

If you’re producing a small number of parts or products, 3D printing can be a more cost-effective solution than traditional manufacturing, which often requires expensive molds and high minimum order quantities.

- When to use: For small-scale production runs, specialty parts, or products that don’t justify mass production.

- Why: It eliminates the need for costly setup, molds, and tooling.

4. Complex or Intricate Designs

3D printing is ideal for complex geometries that are difficult or impossible to produce with traditional manufacturing techniques. This includes intricate patterns, hollow designs, overhangs, and other highly detailed features.

- When to use: When you have a design that requires a high level of detail, internal structures, or geometries that can’t be achieved through conventional methods like CNC machining.

- Why: 3D printing builds objects layer by layer, allowing for greater design freedom.

5. Time-Sensitive Projects

Need something quickly? Best 3D Printing is much faster than conventional manufacturing methods. Whether it’s a part for a machine or a quick prototype for a meeting, 3D printing can drastically reduce lead times.

- When to use: For urgent projects, quick prototypes, or when a part needs to be replaced immediately.

- Why: With no need for molds or extensive setup, 3D printing can cut down production times from weeks to days or even hours.

6. Medical and Healthcare Applications

In the healthcare industry, 3D printing is used for creating patient-specific medical devices, prosthetics, and even bio-printed tissues and organs. It’s a fast-growing area with incredible potential.

- When to use: For custom prosthetics, dental implants, surgical guides, and even personalized medication delivery devices.

- Why: The ability to create custom solutions tailored to the patient’s specific anatomy is something that traditional methods can’t easily achieve.

7. Manufacturing Spare Parts

Instead of maintaining large inventories of spare parts, 3D printing allows companies to create on-demand parts when needed. This is particularly useful in industries like automotive, aerospace, and industrial manufacturing.

- When to use: When you need a replacement part quickly or when the part is no longer in production.

- Why: It eliminates long waiting periods for sourcing parts and reduces the need for large inventories.

8. Education and Research

3D printing is used in schools, universities, and research facilities to help students and professionals create physical models of their designs and concepts. It also allows researchers to produce prototypes of experimental equipment and new inventions.

- When to use: For educational purposes, to teach engineering, design, and STEM subjects, or to develop research prototypes.

- Why: It provides a hands-on approach to learning and experimentation, enabling the creation of functional, testable models.

9. Art and Design

Artists and designers use 3D printing to create unique works of art, sculptures, fashion accessories, and design prototypes. It allows for creative freedom and the realization of complex, previously unachievable designs.

- When to use: For creating artistic pieces, intricate designs, or prototypes for product design.

- Why: 3D printing gives artists the ability to craft intricate details, experiment with different materials, and bring their visions to life in new ways.

10. Tooling and Jigs

In industries like manufacturing, 3D printing is used to create tools, jigs, and fixtures that assist in the assembly or production of other products. This can drastically speed up the production process and reduce costs.

- When to use: When you need a custom tool or jig to streamline production processes.

- Why: 3D printing allows for fast, on-demand creation of highly specialized tools without long lead times or high costs.

11. Architecture and Construction

3D printing is increasingly being used to produce scale models of buildings or even components for construction projects. Some companies are even experimenting with 3D printing entire houses.

- When to use: For architectural modeling, custom components, or potentially even full-scale construction.

- Why: It allows for precise, detailed models that can be created faster and with greater customization than traditional methods.

Summary: When Can You Use 3D Printing?

3D printing is versatile and can be used in a wide range of applications, from rapid prototyping to custom manufacturing, on-demand spare parts, and even medical solutions. Whether you’re working on a time-sensitive project, need intricate designs, or require small-scale production,Best 3D Printing offers an efficient, flexible, and cost-effective solution.

Where we can find the Best 3D Printing services

Finding 3D printing services is easier than ever, thanks to the proliferation of companies and platforms offering these services across various industries. Here’s where you can access 3D printing services:

1. Local 3D Printing Companies

Many cities have specialized 3D printing companies that offer services ranging from prototyping to full-scale production. Here’s how to find them:

- Search Engines: Use Google or other search engines with queries like “3D printing services near me” or “3D printing companies in [your city].”

- Business Directories: Websites like Yelp, Yellow Pages, or local business directories can help you find reputable local services.

- Networking: Ask for recommendations from friends, colleagues, or local business groups.

3. Maker Spaces and Fab Labs

Maker spaces and fabrication labs are community workshops where individuals can access 3D printers, along with other tools and technologies. These spaces often offer classes and support for beginners.

- How to find: Search for “maker spaces” or “fab labs” in your area. Websites like the Fab Foundation provide directories of fabrication labs around the world.

4. University and College Facilities

Many universities and colleges with engineering or design programs have 3D printing facilities. These institutions may offer services to the public or collaborate on projects.

- How to access: Contact local universities with engineering or art programs to inquire about their 3D printing services.

5. Industrial Manufacturing Companies

Some industrial manufacturing firms have integrated 3D printing into their production processes and offer services to external clients. These companies often specialize in creating parts for specific industries.

- How to find: Look for companies in industries like aerospace, automotive, or healthcare that may offer 3D printing as part of their service offerings.

6. 3D Printing Marketplaces

Online marketplaces allow users to connect with 3D printing service providers, often featuring a variety of printers and materials.

- Examples: Platforms like 3D Hubs and connect customers with local and online 3D printing services based on specific needs and preferences.

7. DIY 3D Printing

If you’re interested in hands-on experience and want to print your designs yourself, you can purchase your own 3D printer.

- Where to buy: You can find 3D printers and materials at electronics stores, online marketplaces like Amazon, or specialized retailers like Micro Center or Best Buy.

8. Trade Shows and Events

Industry trade shows often showcase the latest in 3D printing technology and services. Attending these events can connect you with service providers and manufacturers.

- How to find: Look for events like Inside 3D Printing, or local maker fairs and innovation expos in your area.

9. Social Media and Forums

Social media platforms and forums can be great resources for finding recommendations and services.

- Where to engage: Websites like Reddit (specifically the r/3Dprinting subreddit) or Facebook groups dedicated to 3D printing often have members who can recommend local services.

How 3d printing works

3D printing, also known as additive manufacturing, is an innovative process that creates three-dimensional objects from digital designs by building them layer by layer. Here’s a detailed breakdown of how 3D printing works:

1. Designing the 3D Model

The first step in the 3D printing process is to create a digital 3D model. This can be done in several ways:

- CAD Software: Computer-Aided Design (CAD) software like SolidWorks, AutoCAD, is commonly used to create 3D models. Designers can manipulate shapes, sizes, and textures to create the desired object.

- 3D Scanning: If you have an existing object you want to replicate, a 3D scanner can capture its dimensions and create a digital model.

- Online Repositories: There are numerous online platforms where you can find pre-made models that you can download and print.

2. Slicing the Model

Once the 3D model is ready, it needs to be sliced into thin horizontal layers. This is where slicing software comes into play. Popular slicing software includes , and Simplify3D. The slicing process involves:

- Converting the Model: The slicing software translates the 3D model into a series of instructions (G-code) that the 3D printer can understand.

- Layering: It divides the model into numerous layers based on the printer’s capabilities, determining how thick each layer will be.

- Support Structures: If the model has overhangs, the slicing software can generate support structures to ensure the print is stable during printing.

3. Preparing the 3D Printer

Before starting the printing process, you need to prepare the 3D printer:

- Material Loading: Depending on the type of printer, you’ll need to load the appropriate material. This could be a plastic filament (like PLA or ABS), resin, or metal powder.

- Calibration: Ensure the printer is calibrated correctly. This includes leveling the print bed, adjusting nozzle height, and setting temperature settings for the specific material you’re using.

4. Printing the Object

Once everything is set up, the actual printing process begins. The printer follows the G-code instructions generated by the slicing software:

- Layer-by-Layer Building: The printer lays down the material layer by layer. Depending on the technology used, this can involve various methods:

- Fused Deposition Modeling (FDM): The printer melts a thermoplastic filament and extrudes it through a nozzle, depositing it layer by layer.

- Stereolithography (SLA): A laser or projector cures liquid resin into solid layers.

- Selective Laser Sintering (SLS): A laser fuses powdered materials together to form solid layers.

- Cooling and Solidification: As each layer is deposited, it cools and solidifies before the next layer is added. This process continues until the entire object is printed.

5. Post-Processing

After the printing is complete, the object often requires some form of post-processing:

- Removing Support Structures: If supports were used during printing, they need to be carefully removed.

- Cleaning: Depending on the printing method, the object may need cleaning. For instance, SLA prints often require washing in isopropyl alcohol (IPA) to remove uncured resin.

- Finishing Touches: Additional finishing processes may include sanding, painting, or applying coatings to improve the object’s appearance or functionality.

6. Final Product

Once post-processing is complete, the finished 3D printed object is ready for use. It can be used as a prototype, a final product, or even a part in a larger assembly, depending on the application.

Summary of the 3D Printing Process

- Design the 3D Model: Use CAD software or 3D scanning.

- Slice the Model: Convert the model into layers and generate G-code.

- Prepare the Printer: Load material and calibrate settings.

- Print the Object: Build the object layer by layer using the chosen technology.

- Post-Process the Print: Remove supports and clean the object as needed.

- Final Product: The object is ready for use or further processing.

3D printing opens up new possibilities for creativity, manufacturing, and innovation, allowing for the production of complex and customized designs that were previously challenging or impossible to create with traditional methods.

Effective Ways of Using 3D Printing in Manufacturing by Microfactory

Understanding Microfactory

What is a Microfactory?

A microfactory is a compact manufacturing facility that employs advanced technologies, including 3D printing, robotics, and IoT (Internet of Things), to produce goods on a smaller scale. These facilities are designed for flexibility, allowing them to adapt quickly to changes in demand and produce a wide variety of products.

Benefits of Microfactory

- Cost-Effectiveness: Microfactory reduce overhead costs due to their smaller size and lower energy consumption.

- Customization: They enable high levels of customization and personalization in production, catering to specific customer needs.

- Reduced Waste: By using additive manufacturing techniques like 3D printing, microfactory minimize material waste compared to traditional subtractive manufacturing methods.

- Speed to Market: They allow for quicker prototyping and production, speeding up the time it takes to bring products to market.

Get your 3D Printing at affordeble cost now [1]

Challenges and Considerations

1. Material Limitations

While 3D printing offers many advantages, the range of materials that can be used is still evolving. Manufacturers need to be aware of material properties and their suitability for specific applications.

2. Technology Costs

While microfactory reduce many costs, the initial investment in 3D printing technology can be significant. Companies must evaluate their budget and ROI carefully.

3. Expertise and Training

Operating a microfactory with advanced technologies requires skilled personnel. Companies may need to invest in training to ensure their staff can effectively utilize 3D printing technologies.

How microfactory

Microfactory are a new paradigm in manufacturing, representing a shift towards smaller, localized production facilities that leverage advanced technologies like 3D printing, robotics, and automation. Unlike traditional large-scale factories, microfactory are designed to produce goods in smaller batches or even single items, focusing on customization, efficiency, and sustainability. Here’s a closer look at what microfactory are, how they work, and their benefits.

What is a Microfactory?

A microfactory is a compact, flexible manufacturing facility that employs advanced technologies to produce goods efficiently. These factories typically operate on a smaller scale than traditional manufacturing plants and are equipped with various tools and machines, including:

- 3D Printers: For additive manufacturing of complex and customized parts.

- CNC Machines: For precise machining of materials.

- Robotics and Automation: For repetitive tasks and assembly processes.

- IoT Devices: For monitoring and optimizing production processes.

How Microfactory Work

Microfactory utilize a combination of technologies and processes to streamline production. Here’s a breakdown of how they operate:

1. Design and Prototyping

- Digital Design: Products are designed using CAD software, allowing for complex geometries and rapid modifications.

- Rapid Prototyping: 3D printing enables quick iteration of prototypes, allowing for design testing and validation before mass production.

2. Flexible Production

- Batch Sizes: Microfactory can produce small batches or even individual items based on demand, reducing waste and inventory costs.

- Multi-Functionality: Equipment is often multi-functional, capable of handling various processes like printing, machining, and assembly within a single workspace.

3. Localized Manufacturing

- Proximity to Market: Microfactory can be located closer to customers, reducing shipping times and costs. This localization helps in responding quickly to market changes and customer needs.

- Supply Chain Efficiency: By producing goods locally, microfactory can minimize transportation and logistics complexities.

4. Automation and IoT Integration

- Smart Manufacturing: Integration of IoT devices allows for real-time monitoring and data collection, leading to improved efficiency and predictive maintenance.

- Robotic Automation: Automating repetitive tasks enhances precision and speed, reducing human error and labor costs.

5. Sustainable Practices

- Resource Efficiency: Microfactory often focus on using materials more efficiently, minimizing waste through precise production techniques.

- Renewable Energy: Many microfactory incorporate renewable energy sources, like solar panels, to reduce their carbon footprint.

Benefits of Microfactory

Microfactory offer several advantages over traditional manufacturing models:

1. Customization and Flexibility

- Tailored Products: With the ability to produce small batches, microfactory can offer highly customized products that meet specific customer needs.

- Quick Turnaround: Rapid prototyping and localized production allow for fast changes in design and shorter lead times.

2. Cost Efficiency

- Lower Overhead: Microfactory generally require less capital investment than large factories, making them more accessible for startups and small businesses.

- Reduced Waste: By producing only what is needed, microfactory minimize excess inventory and material waste.

3. Agility and Responsiveness

- Market Adaptation: Microfactorys can quickly adapt to changing market demands, allowing companies to pivot and innovate more effectively.

- Local Production: Being close to the end consumer enables manufacturers to respond promptly to feedback and trends.

4. Sustainability

- Eco-Friendly Manufacturing: The focus on efficiency and waste reduction aligns with sustainable practices, contributing to a greener manufacturing process.

- Reduced Transportation Impact: Localized production reduces the carbon footprint associated with long-distance shipping.

5. Empowerment of Small Businesses

- Accessibility: Microfactory provide opportunities for small businesses and entrepreneurs to enter the manufacturing space without the high costs associated with traditional factories.

- Community Engagement: By operating locally, microfactory can engage with the community, supporting local economies and fostering collaboration.

Real-World Examples of Microfactory

Several companies and initiatives exemplify the microfactory model:

- Local Motors: Known for their innovative approach to vehicle manufacturing, they utilize microfactory to produce custom vehicles using advanced technologies like 3D printing and community-driven design.

- Fast Radius: This company operates microfactory that focus on on-demand manufacturing, allowing businesses to create custom parts quickly and efficiently.

- Fablabs: Fabrication laboratories (Fablabs) around the world serve as community microfactory, offering access to 3D printing and other tools for prototyping and small-scale production.

Challenges of Microfactory

While microfactory offer numerous benefits, they also face some challenges:

- Scalability: While microfactory excel at customization, scaling production for larger orders can be a challenge.

- Capital Investment: Although they require less investment than traditional factories, establishing a microfactory still demands significant upfront costs for technology and equipment.

- Market Penetration: Competing with established brands and traditional manufacturing can be challenging, especially in industries with high barriers to entry.

Now more information of manufacturing:

Conclusion

In conclusion, Chicago offers a vibrant ecosystem for Best 3D Printing , with several manufacturers leading the charge in innovation and quality. Whether you’re a seasoned engineer or a budding entrepreneur, these companies provide the resources and expertise needed to turn your ideas into reality. Don’t hesitate to explore the options and find the perfect fit for your 3D printing needs!

FAQs

What types of materials can be used in 3D printing?

3D printing can utilize a variety of materials, including plastics (like ABS and PLA), metals (like titanium and aluminum), and even ceramics. The choice of material often depends on the specific application and requirements.

How long does the 3D printing process take?

The time it takes for 3D printing can vary based on the complexity and size of the object. Simple designs might take a few hours, while more intricate parts can take several days.

Is 3D printing cost-effective?

3D printing can be cost-effective, especially for prototyping and small production runs. However, the overall cost depends on material choices, design complexity, and the quantity produced.

Can 3D printing be used for large-scale manufacturing?

Yes, while traditionally seen as a prototyping method, advancements in technology have made 3D printing viable for larger production runs, particularly for specialized components or customized parts.

What industries benefit from Best 3D Printing ?

A wide range of industries benefit from 3D printing, including aerospace, automotive, healthcare, consumer goods, and architecture. Its ability to create complex geometries and customized solutions makes it valuable across sectors.