CNC Machining

CNC Machining

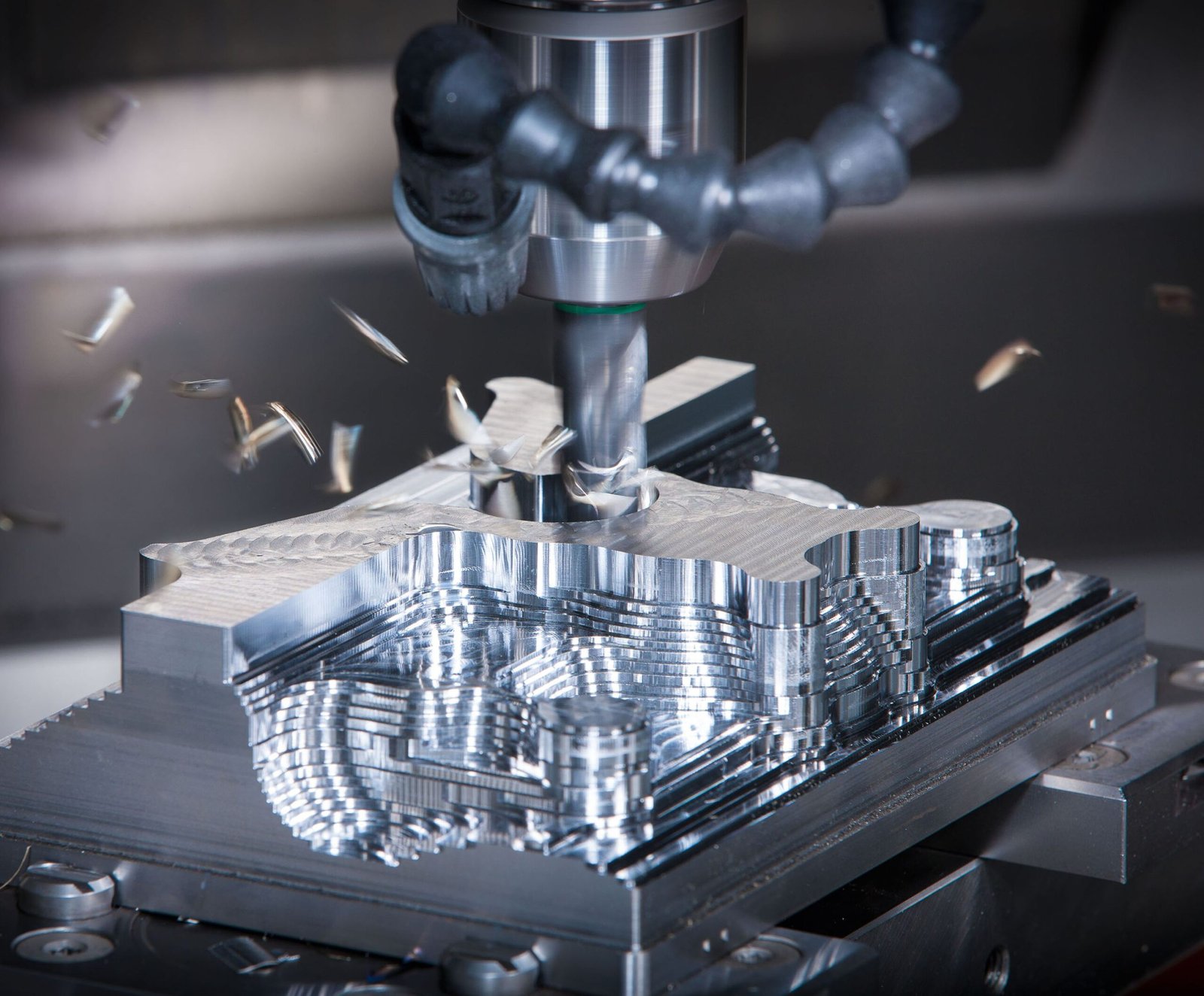

Microfactory has a state-of-the-art CNC machining centre with state-of-the-art machinery and in-house engineering knowledge. Our knowledgeable staff pledges to follow your engineering specifications to the letter. Microfactory is an expert in using bar stock to create high-quality components with precise tolerances.

Moreover, we are proficient in finishing both as-cast and as-forged parts. On completed or semi-finished items, we also manage all necessary secondary processes, such as surface and heat treatment.

Technical Specifications

5-axis CNC Machining Centers: We utilize advanced 5-axis CNC machining centers with spacious work envelopes to handle complex 3D geometries and large workpieces. These machines boast high-speed spindles and rapid tool changers for efficient production.

3+2 Axis Simultaneous Machining: Our advanced CNC machines are capable of 3+2 axis simultaneous machining, allowing us to machine intricate features and contoured surfaces in a single setup. This reduces production time and ensures exceptional accuracy.

We leverage a wide range of cutting tools and employ advanced toolpath programming techniques to optimize machining processes for different materials and part geometries.

We have extensive experience machining a wide range of materials, including: Various grades of aluminum, steel, stainless steel, brass, and copper Engineering plastics like ABS, PEEK, and Delrin. We can also work with specialty materials upon request (consult with our team for details).

We pledge to go above and above your standards for quality. Strict ISO 9001 guidelines are followed in all of our CNC machining procedures.

Among our methods for quality control are:

Inspections carried out while the machine is being worked on

Using coordinate measuring machines, or CMMs, final dimensional checks Inspections of first articles to guarantee that parts fulfil your precise requirements Advantages of Our Cutting-Edge CNC.

Our advanced machinery and processes guarantee tight tolerances and high repeatability for all your parts.

3+2 axis machining and optimized toolpath programming enable efficient production, reducing lead times.

We can handle intricate designs with confidence, thanks to our advanced 5-axis CNC machining capabilities.

We work with a wide range of materials to suit your specific project requirements.

Our commitment to ISO standards and rigorous inspections

Machining Capabilities

With cutting-edge technology and a compassionate approach, we aim to make your Manufacturing experience comfortable and stress-free

Latest News

- Upper Pivot Project – Case Study August 26, 2025

- Texas Truck Suspension Parts Project – Case Study August 26, 2025

- 🛠️ PROJECT SHOWCASE TEMPLATE – MULTI-PROCESS MANUFACTURING August 26, 2025

- Strike Project – Case Study August 26, 2025

Ph. No. & Address

USA: +1 331-215-4181

India: +91 63 5575 2382