Looking for CNC manufacturing companies near me? Whether you’re in aerospace, automotive, or even healthcare, CNC machining plays a crucial role in producing high-quality components with precision. From creating intricate parts to scaling production efficiently, CNC (Computer Numerical Control) manufacturing has transformed the landscape of modern manufacturing. This guide will walk you through everything you need to know about CNC manufacturing, its benefits, and how to choose the best CNC companies.

Table of Contents

What is CNC Manufacturing?

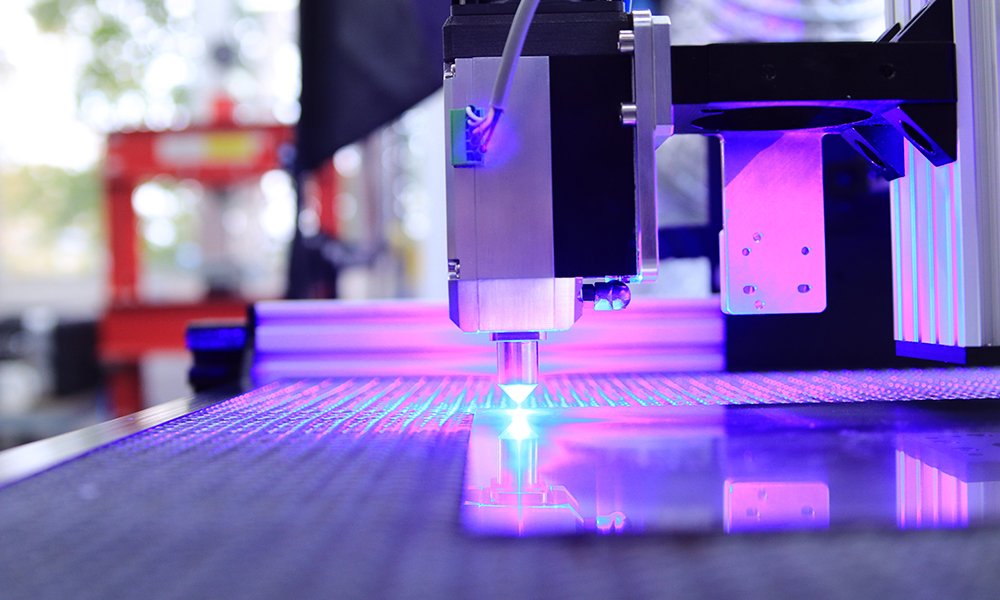

Definition of CNC Manufacturing

CNC manufacturing to the process of using computer-controlled machines to cut, shape, and mold materials into precise parts. it’s metals, plastics, or wood, CNC machines operate based on pre-programmed instructions, making them incredibly accurate and efficient.

Brief History of CNC Machines

CNC technology started in the 1950s, evolving from punched tape systems to the advanced CAD/CAM (Computer-Aided Design/Manufacturing) processes we have today. It revolutionized industries by allowing mass production with tight tolerances and rapid production times.

How to use CNC Manufacturing

To use CNC (Computer Numerical Control) manufacturing effectively, you’ll need to understand the basic steps involved, from design to production. Here’s a step-by-step guide on how to use CNC manufacturing:

1. Design the Part Using CAD Software

- Start with a Design: Create the part you want to manufacture using CAD (Computer-Aided Design) software like SolidWorks, Auto CAD, or Fusion 360. The software allows you to create precise digital models of the parts, specifying dimensions, geometry, and tolerances.

- Choose Materials: Select the right material for your part, whether it’s metal, plastic, wood, or another material. The type of material will impact the CNC machine settings.

2. Convert the Design to CAM Software

- Use CAM Software: Once the design is complete, import the CAD file into CAM (Computer Manufacturing) software, such as Mastercam or Fusion 360. CAM translates the digital design into tool paths that the CNC machine will follow.

- Set Tool Paths: Define cutting paths, speeds, feed rates, and other machine parameters in CAM. This step ensures that the machine operates accurately based on the design.

3. Generate G-Code

- Create the G-Code: CAM software will generate G-code, a machine language that the CNC machine reads to execute the programmed instructions. The G-code tells the machine how to move, cut, or shape the material according to your design.

4. Set Up the CNC Machine

- Prepare the Machine: Set up the CNC machine by securing the material (workpiece) onto the machine bed or fixture. Install the necessary cutting tools, such as end mills,

How CNC Manufacturing Works

The Role of Computers in CNC

At the heart of CNC manufacturing is software that controls the machine. Operators input design specifications into the system, which are then translated into instructions for the machine to follow. These precise command , speed, and accuracy across production runs.

Types of CNC Machines

CNC machines come in different forms depending on the application. Let’s break down the most common ones:

CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece. These machines are highly versatile and ideal for producing intricate components with complex geometries.

CNC Lathes

CNC lathes, on the other hand, rotate the workpiece while the cutting tool remains stationary. They are commonly used for producing cylindrical parts, such as shafts and fittings.

CNC Routers

CNC routers are typically used for cutting softer materials like wood, plastic, or foam. They’re perfect for industries like furniture or signage production.

Benefits of CNC Manufacturing

CNC (Computer Numerical Control) manufacturing offers a wide range of benefits, making it a critical technology for many industries. Here are some key advantages of CNC manufacturing:

1. Precision and Accuracy

- CNC machines are incredibly precise, often achieving tolerances as tight as 0.001 inches. This high level of accuracy is vital for industries like aerospace, automotive, and medical devices, where exact specifications are crucial for performance and safety.

2. Consistency and Repeatability

- Once a program is set up, CNC machines can produce identical parts repeatedly with no variation. This ensures consistency across production runs, which is especially important for large-scale manufacturing or when producing multiple parts that need to fit together perfectly.

3. Increased Efficiency

- CNC machines operate with minimal human intervention, allowing for faster production times. They can work continuously 24/7, significantly increasing throughput while reducing lead times, making them ideal for high-demand manufacturing.

4. Versatility Across Materials

- CNC machines can work with a variety of materials, including metals (aluminum, steel, titanium), plastics, wood, foam, and composites. This versatility allows CNC technology to be used across many industries and applications, from simple prototypes to complex, high-precision components.

5. Reduced Human Error

- Because CNC machines are computer-controlled, the risk of human error during machining is greatly minimized. Once the design is programmed, the machine follows it precisely, reducing the likelihood of mistakes that can occur in manual operations.

6. Cost-Effectiveness

- Although the initial investment in CNC equipment can be high, it leads to significant cost savings over time. Faster production, reduced waste, lower labor costs, and the ability to produce complex parts with minimal errors all contribute to making CNC machining more cost-efficient in the long run.

7. Flexibility in Design and Prototyping

- CNC machines can quickly adapt to different designs, allowing manufacturers to create custom parts or prototypes with ease. This flexibility is beneficial in industries where designs frequently change or where custom components are required.

8. Reduced Waste

- CNC machining is highly efficient in material usage. Because the machine operates with precision, it cuts only the necessary material, reducing waste and optimizing raw material usage. This is particularly important for expensive materials like titanium or specialty plastics.

9. Safety

- CNC machines require minimal human interaction during operation, which enhances workplace safety. Operators are less exposed to dangerous tools and high-speed machining processes, reducing the risk of accidents.

10. Scalability

- Whether you need a single prototype or thousands of parts, CNC machines can easily scale production to meet demand. Once the design is programmed, increasing the quantity of parts is simply a matter of adjusting the production run.

11. Integration with CAD/CAM Software

- CNC manufacturing integrates seamlessly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, making the transition from design to production smoother and more efficient. This digital workflow helps reduce design errors and speeds up the prototyping phase.

12. Global Applicability

- CNC manufacturing is utilized globally, making it easy for companies to source parts from manufacturers anywhere in the world while ensuring consistent quality. This standardization is especially important for companies that operate internationally.

13. Faster Time-to-Market

- CNC machining accelerates production timelines by eliminating many manual processes. This allows businesses to bring new products to market faster, giving them a competitive edge in industries that require rapid prototyping and product iteration.

In summary, CNC manufacturing’s ability to produce precise, consistent, and cost-effective parts with minimal waste and high efficiency makes it a valuable tool for industries that demand accuracy and scalability. Whether for small custom orders or mass production, CNC machining offers significant advantages over traditional manual processes.

Choosing CNC Manufacturing Companies Near me

Factors to Consider

When searching for CNC companies nearby, there are a few key factors to keep in mind. First, think about company reputation. Look for customer reviews and testimonials to gauge their reliability. Secondly, check the equipment and technology they use. Are they up to date with the latest CNC advancements? Finally, factor in lead time and cost. You don’t want to compromise on quality, but budget and delivery timelines are just as important.

Company Reputation

A company’s reputation says a lot about its quality and service. Check online reviews, ask for referrals, or even visit their shop to see their operation firsthand.

Equipment and Technology

Make sure the company uses up-to-date CNC machines. A modern shop should have advanced equipment like 5-axis machines, which offer superior precision and complexity capabilities.

Lead Time and Cost

Different companies offer varying production speeds and costs. Always request quotes and compare them to find the best balance between quality, lead time, and price.

Industries That Use CNC Manufacturing

Aerospace

Aerospace companies rely on CNC for making critical components like turbine blades and engine parts. CNC’s precision is vital in this high-stakes industry, where every fraction of an inch matters.

Automotive

The automotive industry uses CNC to produce everything from engine blocks to interior trim components. It’s a cornerstone in ensuring that parts are mass-produced without losing quality.

Medical

CNC machines help produce medical devices and implants with the high precision necessary to meet stringent health and safety standards. Custom prosthetics and surgical tools are often crafted using CNC machining.

Popular CNC Manufacturing Companies Near me

Local CNC Companies Overview

Local CNC manufacturers can offer both proximity and cost advantages. Companies like Share Machine Inc. (Aurora, IL) provide custom machining for industries like aerospace and electronics. Others, like Path Machining & Automation (Ramsey, MN), specialize in precision machining for the medical and industrial sectors.

Custom vs. Large-Scale Companies

Custom CNC shops often cater to smaller, specialized orders, while larger companies can handle bulk orders. Depending on your project, one may be more suitable than the other.

What to Expect When Working with a CNC Manufacturer

Initial Consultation

The process typically starts with an initial consultation. The manufacturer will discuss your project’s specs, materials, and timelines. This is a crucial step for ensuring they understand your vision.

Prototyping and Design Support

Many CNC manufacturers offer prototyping services, allowing you to see a physical model before moving to full-scale production. Design support is often provided to optimize the part for manufacturing.

Final Production

Once the design is approved, the CNC machines go to work. You can expect precise, consistent results across all units, whether you need 10 or 10,000 parts.

How to Find CNC Manufacturing Companies Near me

Online Search Strategies

Start your search online with terms like “CNC manufacturing near me” or “precision CNC machining.” Many companies offer detailed websites that showcase their services, portfolios, and equipment.

Referrals and Industry Networks

Ask for referrals from colleagues in your industry or attend trade shows where you can meet CNC manufacturers in person. Building relationships in these networks often leads to trusted partnerships.

Visiting Local Machine Shops

If possible, visit local CNC shops. Seeing their equipment and meeting their team can help you feel more confident in your decision.

The Future of CNC Manufacturing

The future of CNC (Computer Numerical Control) manufacturing is poised for significant growth and transformation, driven by advancements in technology, automation, and changing industrial needs. Several trends and innovations are shaping the future of this field:

1. Increased Automation and AI Integration

- Smart Manufacturing: CNC systems will continue to integrate more automation, making factories “smart” and more autonomous. This involves combining CNC with robotics and AI to enhance efficiency, reduce errors, and optimize workflow. AI can help CNC machines learn from past processes, adapt in real-time, and improve their cutting strategies.

- Predictive Maintenance: AI-powered predictive maintenance systems can monitor CNC machines in real-time, predicting when a part may fail or when maintenance is required. This reduces machine downtime and prolongs the lifespan of the equipment.

2. Hybrid Manufacturing Techniques

- Combination of Additive and Subtractive Manufacturing: CNC machining is often viewed as a subtractive process (removing material), while 3D printing is additive (adding material). In the future, hybrid machines that combine both techniques will become more common, offering the best of both worlds: the precision of CNC machining and the material efficiency of 3D printing. This will reduce material waste and allow for more complex part creation.

3. Advancements in 5-Axis CNC Machining

- Increased Complexity and Precision: While many CNC machines currently operate on three axes (X, Y, Z), the future will see more widespread adoption of 5-axis CNC machines. These machines allow for more complex and precise parts to be manufactured in a single operation, reducing the need for multiple setups and improving production speed.

- Improved Surface Finish: 5-axis machining can enhance the surface finish of parts, which is particularly beneficial for industries like aerospace and medical device manufacturing where ultra-smooth surfaces are critical.

4. IoT (Internet of Things) in CNC Manufacturing

- Real-Time Monitoring: IoT allows CNC machines to be connected to networks, enabling real-time data tracking and analytics. This helps operators monitor performance, optimize operations, and predict problems before they occur.

- Remote Control and Monitoring: CNC machines with IoT connectivity can be controlled and monitored remotely, allowing companies to manage multiple facilities from a single location and improving operational flexibility.

5. Sustainability and Green Manufacturing

- Eco-Friendly Materials and Processes: As sustainability becomes a priority for industries, CNC manufacturing is evolving to become more eco-friendly. Companies are focusing on reducing waste, using recyclable materials, and improving energy efficiency in CNC operations.

- Energy-Efficient CNC Machines: Newer CNC machines are being designed with energy conservation in mind, helping to reduce the overall carbon footprint of the manufacturing process.

6. Customization and On-Demand Manufacturing

- Mass Customization: As consumer demands shift toward personalized products, CNC technology will enable manufacturers to efficiently produce custom parts without sacrificing speed or precision. This flexibility will be especially important in industries like automotive, electronics, and healthcare.

- On-Demand Production: CNC machines will become central to on-demand manufacturing services, where companies can produce parts only when needed, reducing inventory costs and waste.

7. Improved Software and CAD/CAM Integration

- Cloud-Based CAD/CAM Systems: The future will see more cloud-based software solutions that allow seamless collaboration, design updates, and more flexible production workflows. These systems will allow engineers and manufacturers to work on projects from anywhere and make real-time adjustments to designs.

- Advanced Simulation Capabilities: CNC software will become more advanced, offering better simulation tools that can predict machining outcomes with high accuracy, helping to reduce trial and error during the prototyping phase.

8. Advanced Materials and Tooling

- New Materials: CNC machines are evolving to handle advanced materials such as composites, ceramics, and exotic alloys. These materials are critical in industries like aerospace and medical devices, where strength, durability, and heat resistance are paramount.

- Improved Cutting Tools: New developments in cutting tool technology, such as carbide and diamond-coated tools, will improve the precision and speed of CNC machines, allowing them to cut harder materials with greater efficiency.

9. Human-Machine Collaboration

- Cobots (Collaborative Robots): In the future, CNC manufacturing will see increased use of cobots, robots designed to work alongside human operators. Cobots can assist in tasks such as material handling, inspection, and tool changes, enhancing productivity while reducing labor costs.

10. Global and Local Production Networks

- Localized Manufacturing Hubs: As supply chains evolve, there will be a shift toward more localized CNC manufacturing hubs that can rapidly respond to regional demands. This will reduce the reliance on long-distance shipping and improve production lead times.

- Global Connectivity: CNC manufacturing will continue to benefit from global networks that allow companies to access a wider range of expertise, materials, and technologies, making it easier to innovate and scale production.

Conclusion

CNC manufacturing has revolutionized how industries produce high-quality parts with unmatched precision. Whether you’re in aerospace or medical fields, CNC offers a level of accuracy and efficiency that’s hard to beat. By understanding how CNC works and knowing what to look for in a local CNC company, you’re better prepared to find the right partner for your project. Ready to get started? The CNC manufacturer near you could be the key to your next breakthrough!

FAQs

1. What does CNC stand for?

CNC stands for Computer Numerical Control, which refers to the use of computers to control machinery in the manufacturing process.

2. How do I find CNC companies near me?

Start with an online search, ask for referrals in your industry, or visit local shops to explore their services and capabilities.

3. What industries rely on CNC manufacturing?

Industries like aerospace, automotive, electronics, and medical all depend on CNC machining for precision parts.

4. How long does it take to produce a CNC part?

Production times vary depending on complexity and order size, but CNC machines typically work quickly and efficiently.

5. Can CNC machines work with any material?

CNC machines can work with a variety of materials including metals, plastics, and wood, offering versatility for different industries.