In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. Companies are continually seeking ways to enhance their production processes, reduce costs, and maintain the highest quality standards. Enter Microfactory, a trailblazer in the realm of CNC (Computer Numerical Control) machining services. But what sets Microfactory apart from the rest? Why is it considered the best in terms of CNC machining service? Let’s dive into the world of Microfactory and uncover the secrets behind its success.

What is CNC Machining?

CNC machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools. This technology allows for precise and complex shaping of materials such as metal, plastic, wood, and composites. The primary advantage of CNC machining is its ability to produce highly accurate and consistent parts, which is essential for industries like aerospace, automotive, and medical devices.

The Rise of Microfactories

What is a Microfactory?

A microfactory is a small-scale, highly flexible manufacturing facility that focuses on producing small batches of high-quality products. Unlike traditional factories, microfactories leverage advanced technologies like CNC machining, 3D printing, and robotics to streamline production processes and reduce waste. These facilities are designed to be agile, allowing for rapid prototyping, customization, and on-demand manufacturing.

Benefits of Microfactories

- Efficiency: Microfactories are designed to optimize production processes, minimizing downtime and maximizing output.

- Flexibility: The ability to quickly adapt to new designs and production requirements makes microfactories ideal for industries with rapidly changing demands.

- Sustainability: By reducing waste and energy consumption, microfactories contribute to more sustainable manufacturing practices.

- Cost-Effectiveness: Small-scale production reduces overhead costs and allows for more competitive pricing.

How Microfactory Excels in CNC Machining Service

State-of-the-Art Technology

Microfactory is at the forefront of technological innovation, utilizing the latest advancements in CNC machining to deliver unparalleled precision and efficiency. From multi-axis machining centers to automated quality control systems, Microfactory ensures that every part meets the highest standards of accuracy and consistency.

Expertise and Experience

With a team of seasoned engineers and technicians, Microfactory boasts a wealth of knowledge and experience in CNC machining. This expertise allows them to tackle even the most complex projects, providing innovative solutions and exceptional results. Their commitment to continuous learning and improvement ensures that they stay ahead of industry trends and technological advancements.

Customer-Centric Approach

Microfactory places a strong emphasis on customer satisfaction. They work closely with clients to understand their specific needs and deliver customized solutions that meet or exceed expectations. Whether it’s a one-off prototype or a large production run, Microfactory’s dedication to quality and service is unwavering.

Rapid Prototyping and Customization

In today’s fast-paced market, the ability to quickly develop and test new products is crucial. Microfactory’s rapid prototyping capabilities allow clients to bring their ideas to life in record time. Their flexible production processes also enable easy customization, ensuring that every part is tailored to the client’s exact specifications.

Quality Assurance

Quality is at the heart of everything Microfactory does. They employ rigorous quality control measures at every stage of the production process, from initial design to final inspection. Advanced metrology equipment and automated inspection systems ensure that every part meets the strictest standards of accuracy and reliability.

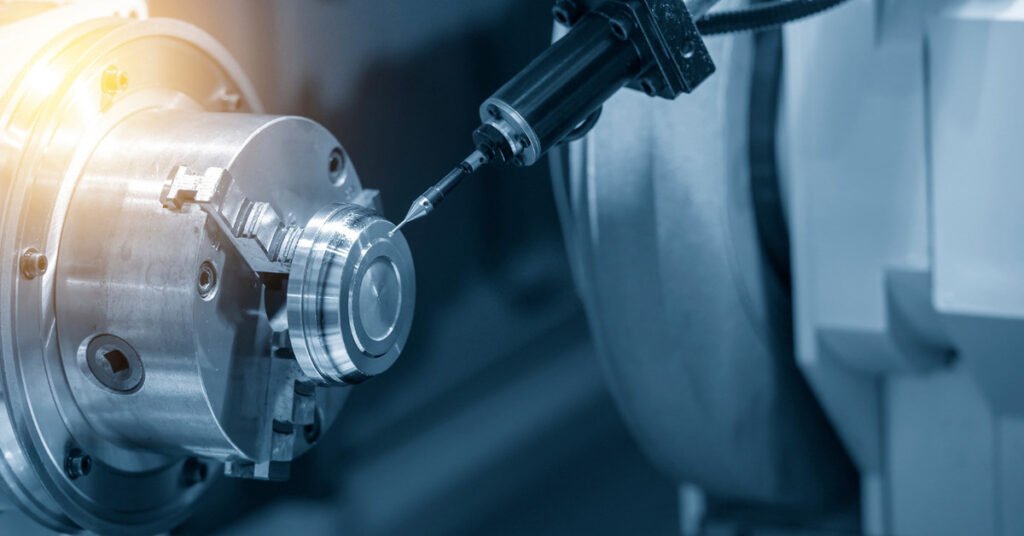

Image of best in terms of CNC machining service

Applications of Microfactory’s CNC Machining Services

Aerospace Industry

The aerospace industry demands the highest levels of precision and reliability. Microfactory’s CNC machining services are ideally suited to produce complex components that meet the stringent requirements of aerospace applications. From turbine blades to structural components, Microfactory delivers parts that are both lightweight and incredibly strong.

Automotive Industry

In the automotive sector, speed and precision are critical. Microfactory’s ability to produce high-quality parts quickly and efficiently makes them a valuable partner for automotive manufacturers. Their CNC machining services are used to create everything from engine components to custom interiors, ensuring that every part meets the industry’s rigorous standards.

Medical Devices

The medical device industry requires components that are not only precise but also biocompatible and safe for use in the human body. Microfactory’s expertise in CNC machining allows them to produce intricate medical components with the highest levels of accuracy and consistency. Whether it’s surgical instruments or implantable devices, Microfactory ensures that every part is made to exacting specifications.

Electronics

In the world of electronics, miniaturization and precision are key. Microfactory’s CNC machining services enable the production of tiny, intricate components that are essential for modern electronic devices. From circuit boards to connectors, Microfactory delivers parts that meet the demanding requirements of the electronics industry.

FAQs About Microfactory’s CNC Machining Services

Q1: What materials can Microfactory work with?

A1: Microfactory is capable of machining a wide variety of materials, including metals (aluminum, steel, titanium), plastics (ABS, polycarbonate, nylon), and composites. Their advanced equipment and expertise allow them to handle even the most challenging materials with ease.

Q2: How does Microfactory ensure the quality of their CNC machined parts?

A2: Microfactory employs stringent quality control measures at every stage of the production process. This includes advanced metrology equipment, automated inspection systems, and rigorous testing protocols to ensure that every part meets the highest standards of accuracy and reliability.

Q3: Can Microfactory handle large production runs?

A3: Yes, Microfactory is equipped to handle both small and large production runs. Their flexible manufacturing processes and state-of-the-art equipment allow them to scale production to meet the specific needs of their clients.

Q4: What is the turnaround time for CNC machining projects at Microfactory?

A4: Turnaround times vary depending on the complexity and volume of the project. However, Microfactory is known for its rapid prototyping capabilities and efficient production processes, ensuring that clients receive their parts as quickly as possible.

Q5: Does Microfactory offer design assistance?

A5: Absolutely. Microfactory’s team of experienced engineers is available to provide design assistance and consultation, helping clients optimize their designs for manufacturability and performance.

Conclusion

In a world where precision, efficiency, and flexibility are paramount, Microfactory stands out as the best in terms of CNC machining service. Their state-of-the-art technology, unparalleled expertise, and customer-centric approach make them a leader in the industry. Whether you’re in aerospace, automotive, medical devices, or electronics, Microfactory has the capabilities to meet your needs and exceed your expectations. Discover the future of precision manufacturing with Microfactory, where innovation meets excellence.