In the ever-evolving world of manufacturing, businesses are constantly seeking innovative solutions to meet their production demands. Traditional manufacturing methods, often characterized by large-scale factories and mass production, are being challenged by a new and dynamic concept: the microfactory. This article delves into how microfactories are leading manufacturing demands by offering unparalleled agility, efficiency, and sustainability. We will explore the benefits of microfactories, address common questions, and discuss the potential future of this transformative approach.

What is a Microfactory?

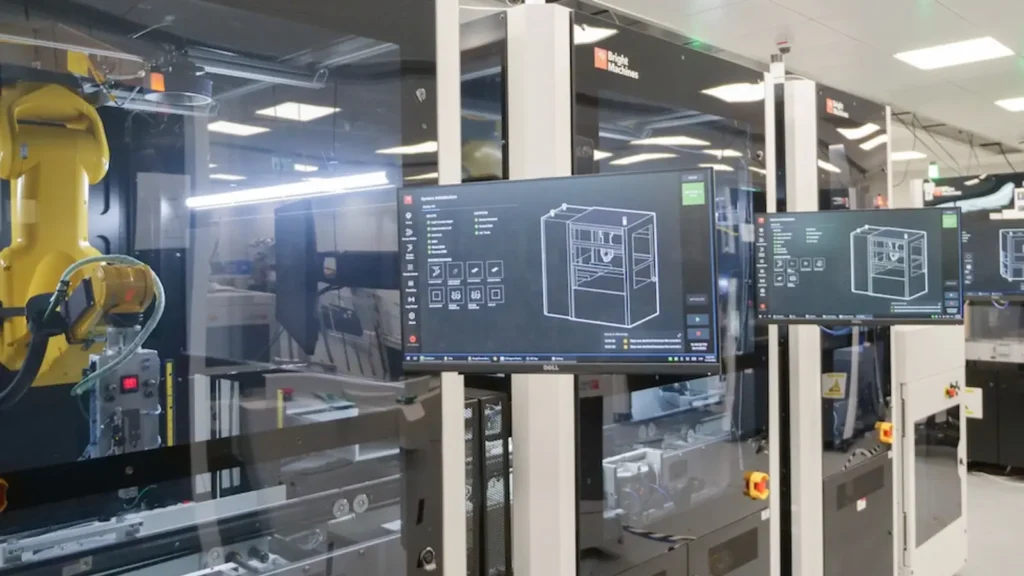

A microfactory is a small-scale, highly automated production facility designed to produce goods in a more flexible and efficient manner compared to traditional factories. These compact facilities leverage advanced technologies such as robotics, 3D printing, and the Internet of Things (IoT) to streamline production processes. The result is a manufacturing environment that can quickly adapt to changing demands and produce high-quality products with minimal waste.

Key Features of Microfactory

- Compact Size: Microfactory occupy a fraction of the space required by traditional factories, often fitting within urban environments.

- Automation: High levels of automation reduce the need for manual labor and increase precision.

- Flexibility: Easily adaptable to different production needs, allowing for rapid shifts in product lines.

- Sustainability: Designed to minimize waste and energy consumption, contributing to environmentally friendly manufacturing practices.

The Benefits of Microfactory

Agility and Responsiveness

One of the most significant advantages of microfactory is their ability to respond quickly to market changes. In today’s fast-paced business environment, being able to pivot production lines and meet new demands promptly is crucial. Microfactory enable businesses to:

- Quickly Prototype and Innovate: With advanced technologies like 3D printing, microfactory can produce prototypes rapidly, allowing for faster innovation cycles.

- Reduce Lead Times: The compact and automated nature of microfactory means that products can be brought to market much faster than through traditional manufacturing methods.

- Customize Products: Microfactory can easily handle small-batch and customized production runs, catering to niche markets and specific customer needs.

Efficiency and Cost Savings

Microfactory are designed to optimize efficiency and reduce costs in several ways:

- Lower Overhead Costs: Smaller facilities mean lower expenses related to real estate, utilities, and maintenance.

- Reduced Waste: Advanced manufacturing techniques and precise automation result in less material waste.

- Energy Efficiency: Modern microfactory often incorporate sustainable energy solutions, reducing overall energy consumption.

Sustainability and Environmental Impact

In an era where environmental concerns are paramount, microfactory offer a more sustainable approach to manufacturing:

- Localized Production: By situating microfactory closer to end consumers, transportation-related emissions are significantly reduced.

- Resource Optimization: Efficient use of materials and energy helps minimize the environmental footprint of manufacturing processes.

- Recycling and Reuse: Many microfactory incorporate recycling programs and reuse strategies, further reducing waste.

Challenges and Considerations

While the benefits of microfactory are substantial, there are also challenges to consider:

- Initial Investment: Setting up a microfactory requires a significant initial investment in advanced technologies and infrastructure.

- Skilled Workforce: Operating a highly automated facility necessitates a skilled workforce proficient in handling advanced machinery and software.

- Scalability: While microfactory excel at small-scale and customized production, scaling up to meet large-scale demands can be challenging.

Images of How Microfactory lead your Manufacturing Demands

Case Studies: Microfactory in Action

Local Motors: Revolutionizing Automotive Manufacturing

Local Motors is a prime example of how microfactory can transform an industry. By utilizing microfactory, Local Motors has been able to:

- Produce Custom Vehicles: Their microfactory enable the production of customized vehicles tailored to specific customer requirements.

- Innovate Rapidly: With the ability to quickly prototype and iterate, Local Motors brings innovative vehicle designs to market faster than traditional automotive manufacturers.

- Reduce Environmental Impact: By using localized production and advanced manufacturing techniques, Local Motors minimizes waste and reduces transportation emissions.

Rothy’s: Sustainable Footwear Production

Rothy’s, a sustainable footwear company, leverages microfactory to produce eco-friendly shoes. Their approach includes:

- 3D Knitting Technology: Utilizing 3D knitting machines, Rothy’s creates shoes with minimal waste and optimal material usage.

- Localized Production: Microfactory located near their key markets help reduce shipping distances and associated emissions.

- Recycling Initiatives: Rothy’s incorporates recycled materials into their production process, further enhancing their sustainability efforts.

Future Potential of Microfactory

The future of microfactory looks promising, with several trends indicating continued growth and innovation:

- Integration of AI and IoT: The incorporation of artificial intelligence and the Internet of Things will further enhance automation, efficiency, and adaptability.

- Expansion into New Industries: As the benefits of microfactory become more widely recognized, we can expect to see their adoption across various industries, from electronics to food production.

- Increased Customization: The ability to produce highly customized products will drive demand for microfactory, particularly in industries where personalization is key.

FAQs

What are the main advantages of microfactory?

Microfactory offer several advantages, including increased agility, efficiency, and sustainability. They enable quick prototyping, reduce lead times, lower overhead costs, minimize waste, and have a smaller environmental footprint.

Are microfactory suitable for all types of manufacturing?

While microfactory excel in small-scale, customized, and localized production, they may not be suitable for large-scale mass production. Industries that benefit most from microfactory are those that require flexibility, innovation, and sustainability.

How do microfactory contribute to sustainability?

Microfactory contribute to sustainability by reducing waste, optimizing resource usage, and minimizing transportation-related emissions through localized production. They often incorporate energy-efficient technologies and recycling initiatives.

What challenges do companies face when adopting microfactory?

Companies may face challenges such as the high initial investment in technology and infrastructure, the need for a skilled workforce, and potential difficulties in scaling up production to meet large-scale demands.

Conclusion

Microfactory represent a revolutionary shift in the manufacturing landscape, offering a more agile, efficient, and sustainable approach to production. By leveraging advanced technologies and compact, automated facilities, microfactory can meet the dynamic demands of modern markets while minimizing environmental impact. As industries continue to evolve, the role of microfactory is poised to grow, driving innovation and sustainability in manufacturing. Whether you’re a small business looking to innovate or a large corporation seeking to enhance efficiency, microfactory provide a compelling solution to lead your manufacturing demands.