Prototyping and Pre-Production

Prototyping and Pre-Production

- Pre-production refers to the stage where prototypes are refined and prepared for the manufacturing process. This stage ensures that the product design is production-ready and can be manufactured at scale without issues.

- Importance: Creating pre-production prototypes is essential for confirming the feasibility of manufacturing, assessing production costs, and ensuring quality control.

- Process: It involves detailed testing, finalizing materials, and refining the design to ensure consistency and efficiency in mass production

Technical Specifications

We offer a variety of rapid prototyping technologies to create functional models for design verification and testing before full-scale production.

These technologies include: 3D Printing: Utilizing additive manufacturing techniques to create 3D models from digital designs in various materials like ABS, nylon, and stereolithography resins.

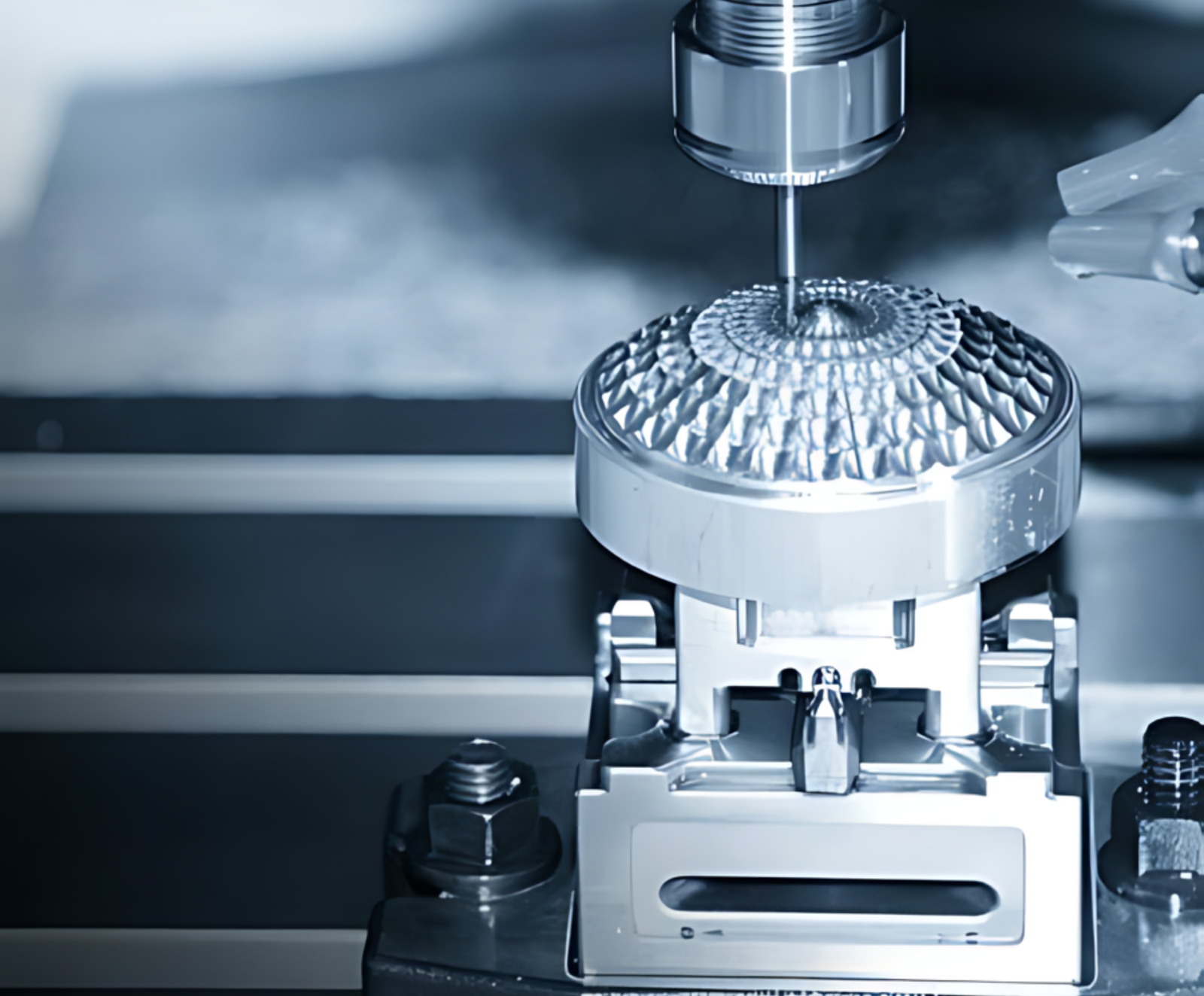

CNC Machining: Employing CNC machining for rapid production of low-volume, high-precision prototypes from various materials.

The materials used for prototyping depend on the chosen technology and project requirements. We offer a wide range of materials for 3D printing and CNC machining to best suit your needs.

Our quality control measures for prototypes ensure dimensional accuracy and functionality. This includes:

Post-processing and finishing of 3D printed parts Dimensional checks of prototypes using calipers or CMMs (for CNC machined prototypes) Functional testing of prototypes to identify any design flaws

Our advanced machinery and processes guarantee tight tolerances and high repeatability for all your parts.

3+2 axis machining and optimized toolpath programming enable efficient production, reducing lead times.

We can handle intricate designs with confidence, thanks to our advanced 5-axis CNC machining capabilities.

We work with a wide range of materials to suit your specific project requirements.

Our commitment to ISO standards and rigorous inspections

Machining Capabilities

With cutting-edge technology and a compassionate approach, we aim to make your Manufacturing experience comfortable and stress-free

Latest News

- Upper Pivot Project – Case Study August 26, 2025

- Texas Truck Suspension Parts Project – Case Study August 26, 2025

- 🛠️ PROJECT SHOWCASE TEMPLATE – MULTI-PROCESS MANUFACTURING August 26, 2025

- Strike Project – Case Study August 26, 2025

Ph. No. & Address

USA: +1 331-215-4181

India: +91 63 5575 2382