Ever heard of 3D printing and wondered what all the fuss is about? This groundbreaking technology has been making waves in various industries, from healthcare to fashion, and it’s not slowing down anytime soon. So, what is 3D printing, and how does it work? Let’s dive into this fascinating world and unravel the mysteries behind it.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. Unlike traditional manufacturing methods that remove material through cutting or drilling, 3D printing builds objects layer by layer, adding material precisely where it’s needed.

A Brief History

Believe it or not, the concept of 3D printing has been around since the 1980s. Chuck Hull invented the first 3D printer in 1983, using a process called stereolithography. Since then, the technology has evolved rapidly, becoming more accessible and affordable.

How Does 3D Printing Work?

Now, let’s get to the nitty-gritty: how does 3D printing work? It’s a bit like baking a cake, but instead of flour and sugar, you’re using materials like plastic, metal, or resin.

The Basic Steps

- Design the Model: The first step is creating a 3D model using computer-aided design (CAD) software. You can either design it from scratch or download a pre-made model from online repositories.

- Convert to STL Format: The CAD file is then converted into STL (stereolithography) format, which breaks the model into thin layers.

- Slice the Model: Using slicing software, the STL file is sliced into hundreds or thousands of layers. This step generates a G-code file, which guides the 3D printer on how to build the object layer by layer.

- Set Up the Printer: Load the chosen material into the 3D printer. Materials can vary widely, from plastic filaments (like PLA and ABS) to metals and ceramics.

- Print the Object: The printer reads the G-code and begins the layer-by-layer construction. Depending on the complexity and size, this process can take anywhere from a few minutes to several hours.

- Post-Processing: Once the printing is done, some objects might need additional work, like removing supports, sanding, or painting.

Types of 3D Printing Technologies

There are several different 3D printing technologies, each suited for different applications:

- Fused Deposition Modeling (FDM): The most common and affordable method, using thermoplastic filaments.

- Stereolithography (SLA): Uses a laser to cure liquid resin into hardened plastic.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered material.

- Digital Light Processing (DLP): Similar to SLA but uses a digital light projector.

- Electron Beam Melting (EBM): Uses an electron beam to melt metal powder.

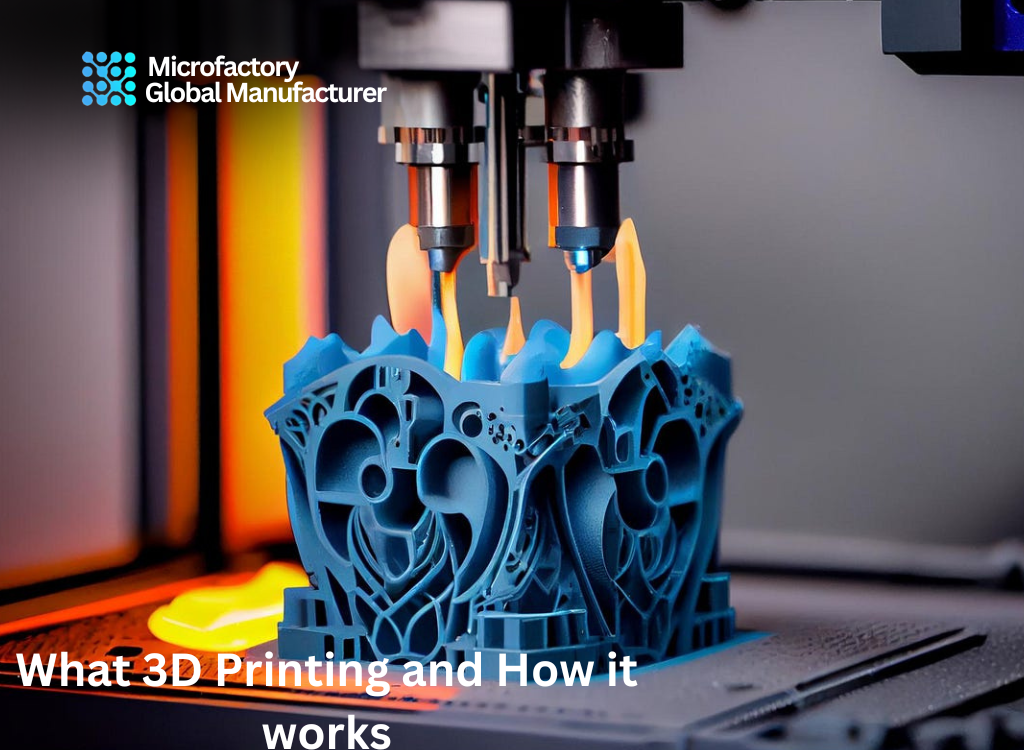

images of 3D printing

Applications of 3D Printing

3D printing isn’t just for geeks and hobbyists. It’s revolutionizing industries and making previously impossible ideas a reality.

Healthcare

In the medical field, 3D printing is used to create custom prosthetics, dental implants, and even bioprinted organs. Surgeons can also use 3D-printed models for pre-surgery planning, improving precision and outcomes.

Automotive and Aerospace

Car manufacturers and aerospace companies use 3D printing to produce lightweight parts, reduce waste, and speed up prototyping. NASA even 3D-prints tools and parts aboard the International Space Station!

Fashion and Art

From avant-garde fashion pieces to intricate sculptures, artists and designers are pushing the boundaries of creativity with 3D printing. It allows for the creation of complex, customized designs that were previously unattainable.

Education and Research

In schools and universities, 3D printing is a fantastic educational tool. It helps students understand complex concepts through hands-on learning and allows researchers to create models and prototypes for their studies.

The Future of 3D Printing

What’s next for 3D printing? The future looks incredibly promising with ongoing advancements and innovations.

Mass Customization

Imagine a world where you can customize everything from your shoes to your car parts. 3D printing makes mass customization possible, catering to individual preferences and needs.

Sustainability

3D printing has the potential to be more environmentally friendly than traditional manufacturing. It reduces waste by using only the material needed and enables local production, cutting down on transportation emissions.

Space Exploration

As mentioned earlier, 3D printing is already being used in space. Future missions might involve 3D-printing habitats on Mars or the Moon, using local materials and reducing the need for heavy cargo launches.

Medical Breakthroughs

Bioprinting is a rapidly evolving field, with researchers working on printing functional organs and tissues. This could revolutionize transplant medicine and reduce the dependency on donor organs.

FAQs

What materials can be used in 3D printing?

You can use a variety of materials in 3D printing, including plastics (like PLA and ABS), metals (like titanium and stainless steel), resins, ceramics, and even edible materials like chocolate!

How long does it take to 3D print something?

The time it takes to 3D print an object depends on its size and complexity. It can take anywhere from a few minutes to several days for large, intricate designs.

Is 3D printing expensive?

The cost of 3D printing has decreased significantly over the years. While high-end industrial printers can be pricey, there are affordable options for hobbyists and small businesses. The cost also depends on the material used and the size of the object.

Can I 3D print at home?

Absolutely! There are many consumer-grade 3D printers available that are user-friendly and suitable for home use. They’re great for DIY projects, prototypes, and educational purposes.

What are the limitations of 3D printing?

While 3D printing is incredibly versatile, it does have some limitations. These include the speed of printing, the size of printable objects, material properties, and the need for post-processing.

Conclusion

3D printing is a game-changer, transforming industries and sparking innovation across the globe. From its humble beginnings in the 1980s to the cutting-edge applications of today, this technology continues to push the boundaries of what’s possible. Whether you’re a hobbyist looking to print your next project or a business exploring new manufacturing methods, understanding what 3D printing is and how it works is key to unlocking its full potential. So, go ahead, dive into the world of 3D printing and see what you can create!