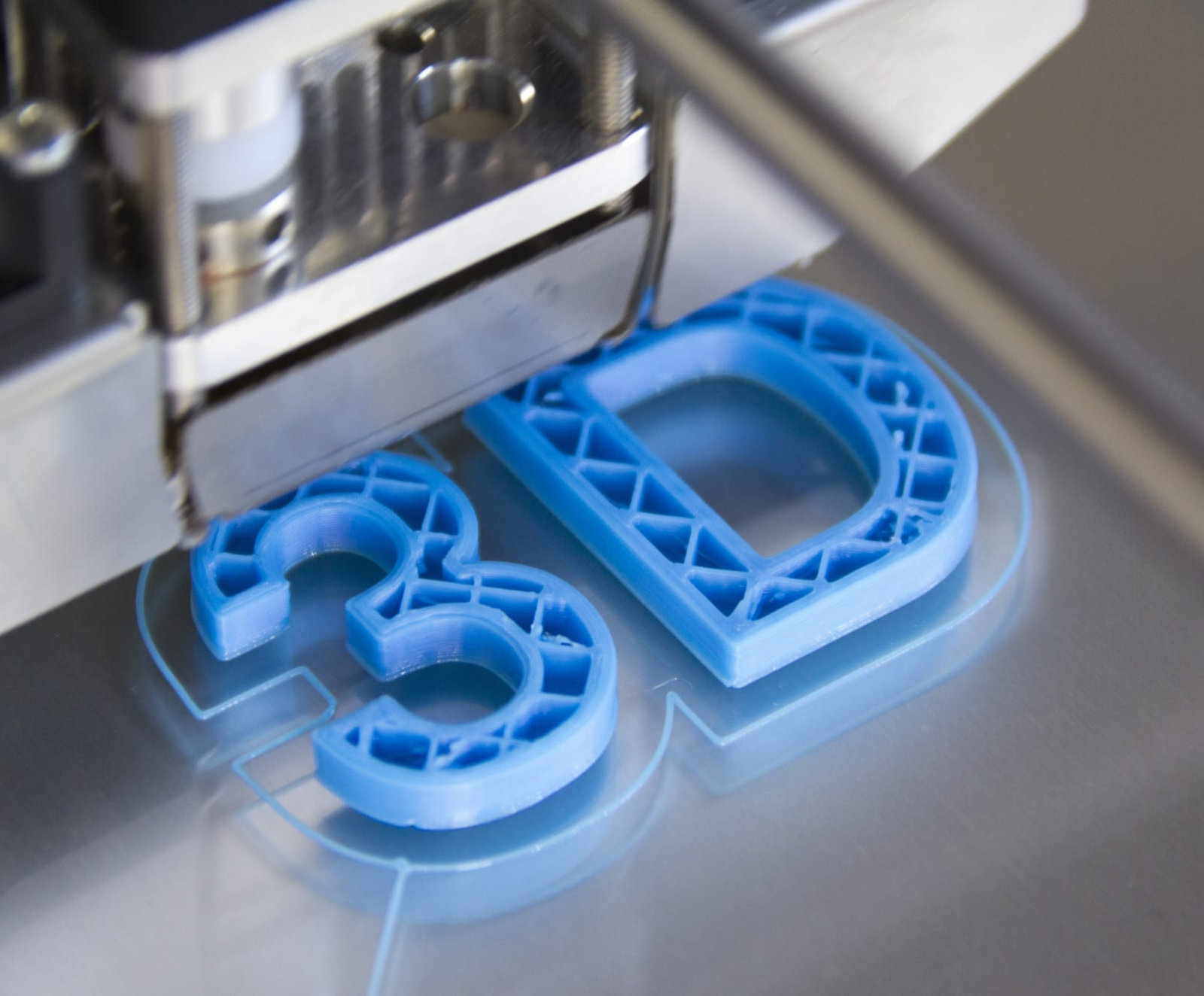

3D Printing

3D printing, also known as additive manufacturing, involves various processes, materials, machinery, and quality control measures. The primary processes include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP).

Technical Specifications

FDM is widely used due to its affordability and accessibility, involving the extrusion of thermoplastic filaments through a heated nozzle to build objects layer by layer.

SLA utilizes a UV laser to cure liquid resin into hardened plastic in a layer-by-layer fashion, offering high-resolution prints with fine details.

The machinery used in 3D printing ranges from desktop units like the Prusa i3 and Ultimaker series for FDM, Formlabs and Anycubic for SLA, to industrial machines like the EOS and 3D Systems for SLS.

These machines vary in build volume, layer resolution, and material compatibility, catering to different user needs from hobbyists to industrial manufacturers.

Common materials include PLA, ABS, PETG, and TPU, each offering distinct properties such as ease of printing, strength, flexibility, and temperature resistance.

Materials for SLA include various photopolymers that can be formulated to achieve different mechanical properties and surface finishes.

Advanced quality control techniques involve the use of software for automated defect detection and correction, as well as non-destructive testing methods like ultrasound or X-ray inspection for internal defect analysis. These measures ensure that the final printed products meet the required specifications and performance standards, enhancing the reliability and functionality of 3D printed components.

Our advanced machinery and processes guarantee tight tolerances and high repeatability for all your parts.

3+2 axis machining and optimized toolpath programming enable efficient production, reducing lead times.

We can handle intricate designs with confidence, thanks to our advanced 5-axis CNC machining capabilities.

We work with a wide range of materials to suit your specific project requirements.

Our commitment to ISO standards and rigorous inspections

Machining Capabilities

With cutting-edge technology and a compassionate approach, we aim to make your Manufacturing experience comfortable and stress-free

Latest News

- Upper Pivot Project – Case Study August 26, 2025

- Texas Truck Suspension Parts Project – Case Study August 26, 2025

- 🛠️ PROJECT SHOWCASE TEMPLATE – MULTI-PROCESS MANUFACTURING August 26, 2025

- Strike Project – Case Study August 26, 2025

Ph. No. & Address

USA: +1 331-215-4181

India: +91 63 5575 2382