When it comes to precision and efficiency in modern manufacturing, CNC Turn Mill Centers are absolute game-changers. These machines are at the heart of industries like aerospace, automotive, and medical devices. And guess what? Chicago is a hotbed for CNC Turn Mill Center manufacturing. Let’s dive into the details and uncover why this vibrant city is a leader in this field.

Table of Contents

Understanding CNC Turn Mill Centers

To appreciate their impact, it’s important to understand what CNC Turn Mill Centers are all about. These machines combine turning and milling operations into one seamless process, making them the backbone of precision manufacturing.

What is a CNC Turn Mill Center?

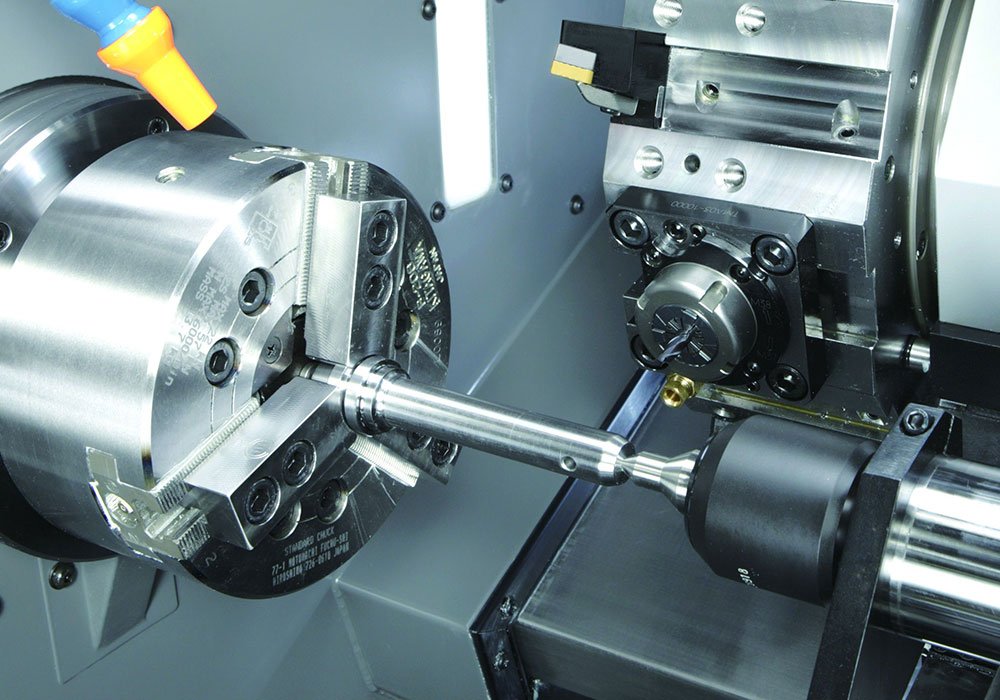

Think of a CNC Turn Mill Center as a multitasking wizard. It’s a machine tool that integrates turning (spinning a part) and milling (cutting it into shape) into a single setup. This hybrid functionality saves time, reduces errors, and boosts productivity. Whether you’re creating intricate aerospace parts or sleek automotive components, these machines can do it all.

Key Components of a CNC Turn Mill Center

Ever wonder what makes these machines tick? The magic lies in their components:

- Spindles: These hold and rotate the workpiece or cutting tool.

- Turrets: These are multi-tool carousels enabling quick tool changes.

- Controllers: The brain of the machine, handling programming and precision.

Together, these parts work in harmony to create precise and complex parts with ease.

The Importance of CNC Turn Mill Centers

CNC Turn Mill Centers are more than just advanced machinery; they represent the pinnacle of precision and efficiency in manufacturing. These machines play a vital role in industries that demand high accuracy, consistency, and productivity. Let’s explore why CNC Turn Mill Centers have become indispensable in modern production processes.

Benefits of Using CNC Turn Mill Centers

CNC Turn Mill Centers combine the best of turning and milling operations into one compact, powerful unit. Why does this matter? Here are some key benefits:

- Precision: CNC Turn Mill Centers deliver results with astonishing accuracy, down to microns. This level of precision is crucial in fields like aerospace and medical devices where even a slight error can have significant consequences.

- Efficiency: These machines streamline production by consolidating multiple steps into a single setup. This reduces the time and effort required, saving manufacturers money while increasing output.

- Flexibility: Whether you’re producing simple parts or intricate, complex designs, CNC Turn Mill Centers can handle it all, adapting to diverse production needs without sacrificing quality.

Enhancing Production Efficiency

One of the biggest advantages of CNC Turn Mill Centers is how they boost production efficiency. By combining turning and milling into a single operation, these machines eliminate the need to transfer workpieces between multiple setups. This saves valuable time and minimizes the risk of errors caused by handling.

With automated tool changes and advanced programming capabilities, manufacturers can complete jobs faster, achieving high output levels without compromising on quality.

Ensuring Consistent Quality

Consistency is king in manufacturing, and CNC Turn Mill Centers excel at delivering it. Unlike manual processes, these machines are controlled by advanced computer systems that execute precise instructions every time. This ensures that every part in a batch meets the exact specifications, regardless of its complexity or volume.

By reducing the risk of human error, CNC Turn Mill Centers not only improve product quality but also enhance the reputation of manufacturers. After all, reliability is a cornerstone of success in competitive markets.

Minimizing Downtime and Waste

Another critical aspect of CNC Turn Mill Centers is their ability to minimize downtime and material waste. With optimized programming and real-time monitoring, manufacturers can detect potential issues early and make adjustments on the fly.

These machines are also designed to use materials efficiently, producing less scrap compared to traditional methods. For industries striving to cut costs and adopt more sustainable practices, this is a significant advantage.

Driving Innovation in Manufacturing

CNC Turn Mill Centers are not just tools; they are enablers of innovation. By providing the capability to produce complex geometries and intricate designs, they empower manufacturers to push the boundaries of what’s possible. From lightweight aerospace components to custom medical implants, these machines open doors to new possibilities in engineering and design.

In summary, CNC Turn Mill Centers are essential to modern manufacturing because they combine precision, efficiency, and flexibility in one powerful package. They not only meet the high demands of today’s industries but also drive innovation and sustainability for the future. Whether it’s reducing production times, maintaining consistent quality, or enabling cutting-edge designs, CNC Turn Mill Centers are truly at the heart of manufacturing excellence.

Why Chicago is a Hub for CNC Turn Mill Center Manufacturing

Chicago is not only famous for its deep-dish pizza and stunning skyline but also for its industrial prowess. Over the years, the Windy City has emerged as a key player in CNC Turn Mill Center manufacturing. But why has Chicago become such a hub for this advanced technology? Let’s break it down.

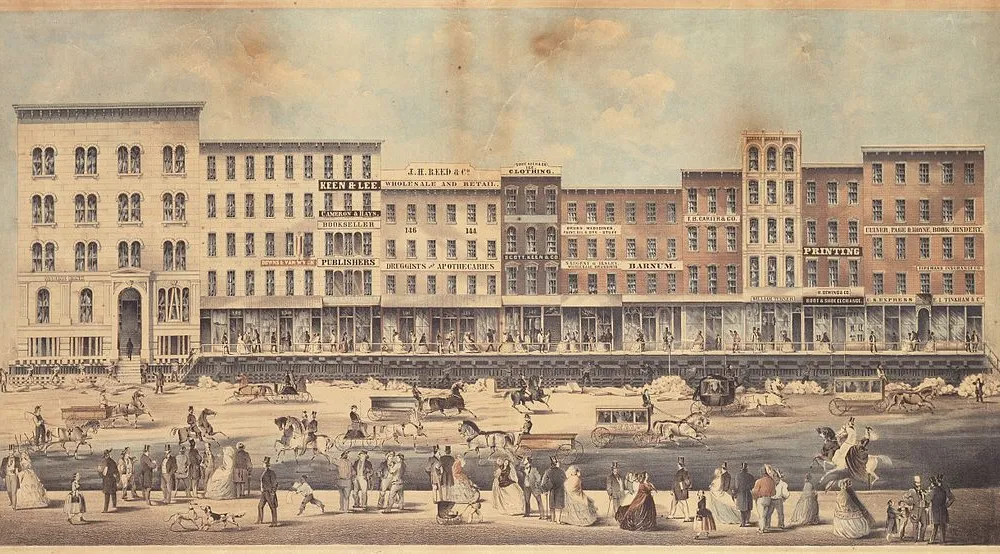

Industrial History of Chicago

Chicago’s reputation as a manufacturing powerhouse dates back to the 19th century when it became a major transportation hub for railroads and shipping. This accessibility made it an ideal location for industries to thrive. Over time, the city evolved into a leader in steel production, machinery, and tools, laying the groundwork for its current dominance in CNC machining.

The city’s historical focus on innovation and industry set the stage for its leadership in advanced manufacturing. This deep-rooted industrial legacy gives local manufacturers a competitive edge, providing a wealth of expertise and infrastructure to support CNC Turn Mill Center production.

Strategic Location and Accessibility

Chicago’s central location in the United States is another major advantage. It serves as a logistics hub with excellent connectivity via road, rail, air, and waterways. This makes it easier for manufacturers to source raw materials and deliver finished products to customers across the country and beyond.

Additionally, being close to other major industrial regions ensures access to a wide network of suppliers and partners, streamlining the production and distribution process.

Skilled Workforce Availability

One of the strongest pillars of Chicago’s CNC Turn Mill Center manufacturing industry is its skilled workforce. The city boasts a deep pool of experienced machinists, engineers, and technicians, thanks to its strong educational institutions and vocational training programs.

Colleges and technical schools in the region offer specialized programs in manufacturing technology, machining, and engineering. Graduates are well-equipped with the knowledge and hands-on experience needed to excel in CNC machining, ensuring a steady supply of talent for local companies.

A Culture of Innovation

Chicago has always been a city that embraces innovation, and its CNC Turn Mill Center manufacturers are no exception. Companies in the region are known for adopting cutting-edge technologies like AI, IoT, and automation to enhance their production capabilities. This culture of innovation has allowed local businesses to stay competitive on a global scale, attracting clients from diverse industries.

Supportive Ecosystem for Manufacturers

Chicago provides a robust ecosystem that supports manufacturers at every stage. From suppliers of high-quality machine parts to research institutions developing the latest machining technologies, the city offers resources that are critical to success in CNC Turn Mill Center manufacturing.

Local trade associations and business groups also play a vital role by fostering collaboration and providing networking opportunities. Events like trade shows and manufacturing expos further enhance Chicago’s reputation as a hub for industrial innovation.

Proximity to Diverse Industries

Another factor that makes Chicago a prime location for CNC Turn Mill Center manufacturing is its proximity to a variety of industries that rely on precision machining. Key sectors such as aerospace, automotive, healthcare, and defense have a strong presence in the region. This creates a symbiotic relationship where local manufacturers can closely collaborate with these industries to meet their specific needs.

Leading Manufacturers in Chicago

If you’re looking for top-notch CNC Turn Mill Centers, Chicago has you covered. The city is home to some of the industry’s most innovative manufacturers.

Company Profiles

Take XYZ Precision, for example. Known for their cutting-edge designs and unparalleled customer service, they’re a leader in the field. Or look at Chicago Tool Works, where innovation meets reliability. These companies are shaping the future of CNC machining.

Innovation in CNC Technology

Chicago-based companies aren’t just keeping up with trends; they’re setting them. From AI integration to smarter designs, they’re pushing the boundaries of what CNC machines can do.

Key Applications of CNC Turn Mill Centers

These versatile machines aren’t just for show. They play a critical role in a wide range of industries. Here’s a quick rundown:

Aerospace and Defense

In aerospace, precision is everything. CNC Turn Mill Centers are used to create complex, high-strength components like turbine blades and structural parts.

Automotive Industry

When it comes to building cars, efficiency and precision are key. These machines help produce everything from engine components to intricate gear systems.

Medical Devices

Need a surgical instrument or a prosthetic device? CNC Turn Mill Centers make it possible, delivering the accuracy needed for life-saving applications.

Future Trends in CNC Turn Mill Center Manufacturing

The world of CNC machining is constantly evolving. So, what’s next? Let’s peek into the future.

Automation and AI Integration

Imagine machines that not only cut and shape but also learn and adapt. With AI integration, CNC Turn Mill Centers are becoming smarter, paving the way for custom manufacturing at scale.

Sustainability in Manufacturing

Eco-friendly practices are gaining traction. Manufacturers are now focusing on energy-efficient machines and sustainable production methods to minimize environmental impact.

How to Choose the Right CNC Turn Mill Center Manufacturer

Selecting the right CNC Turn Mill Center manufacturer is one of the most critical decisions for your business. It can significantly impact your production efficiency, product quality, and overall success. But with so many options available, how do you choose the right one? Let’s break it down step by step.

1. Assess Your Manufacturing Needs

Before diving into the search, it’s essential to understand your specific requirements.

- What type of parts do you produce? Determine the complexity, size, and material of the components you manufacture.

- What is your production volume? High-volume production may demand more robust machines.

- What level of precision is required? Industries like aerospace and medical devices often require ultra-precise tolerances.

Knowing these details will help you narrow down manufacturers that offer machines tailored to your needs.

2. Look for Industry Experience

Experience matters. A manufacturer with a long track record in CNC Turn Mill Center production is more likely to deliver reliable and high-quality machines.

- Check their portfolio to see the types of machines they’ve built and the industries they serve.

- Ask for case studies or client references to understand how their products perform in real-world applications.

Companies with extensive experience are often better equipped to handle unique requirements and provide effective solutions.

3. Evaluate Machine Quality

The quality of the machine directly affects your production capabilities. When evaluating manufacturers, pay close attention to:

- Build Quality: Is the machine constructed with durable materials that can withstand heavy use?

- Precision and Accuracy: Does the manufacturer guarantee tight tolerances and repeatability?

- Technology Integration: Look for features like advanced controllers, AI capabilities, and automation options.

Inspecting a demo machine or visiting a client site can give you a firsthand view of the product quality.

4. Check Certifications and Standards

Reputable manufacturers often have certifications that demonstrate their commitment to quality and safety. Look for standards such as:

- ISO 9001: Indicates a focus on quality management systems.

- CE Certification: Ensures compliance with European safety standards.

- Industry-Specific Certifications: Such as AS9100 for aerospace or ISO 13485 for medical devices.

These certifications ensure that the machines meet rigorous quality and safety benchmarks.

5. Consider After-Sales Support

Buying a CNC Turn Mill Center isn’t just about the machine—it’s about the ongoing relationship with the manufacturer. Strong after-sales support can make or break your experience. Key considerations include:

Training Programs: Look for manufacturers that offer training to help your team get the most out of the machine.

Warranty Coverage: Understand what’s included in the warranty and for how long.

Technical Support: Does the manufacturer provide 24/7 support to address any issues?

Spare Parts Availability: Ensure replacement parts are readily available to minimize downtime.

Conclusion

CNC Turn Mill Centers are the unsung heroes of modern manufacturing, and Chicago is at the forefront of this industry. With its rich history, skilled workforce, and innovative companies, the city is shaping the future of CNC machining. Whether you’re in aerospace, automotive, or healthcare, these machines are revolutionizing the way we build and create.

FAQs

- What is the primary purpose of a CNC Turn Mill Center?

To combine turning and milling operations in one machine, saving time and improving accuracy. - Why is Chicago a leader in CNC Turn Mill Center manufacturing?

Its industrial history, skilled workforce, and innovative companies make it a hub for this technology. - What industries benefit most from CNC Turn Mill Centers?

Aerospace, automotive, and medical device industries heavily rely on these machines. - How do I choose the best CNC Turn Mill Center manufacturer?

Look for quality certifications, customer support, and a proven track record. - What are the latest trends in CNC machining?

AI integration and sustainable manufacturing are the big trends shaping the future.