Fabrication and Assembly

Fabrication and Assembly

In the realm of manufacturing, fabrication and assembly play crucial roles in bringing products to life. Fabrication involves the creation of parts or structures through various processes, while assembly involves putting these parts together to form a functional product. These processes are the backbone of industries ranging from automotive to aerospace, and understanding them is essential for achieving quality and efficiency in production.

Technical specifications are detailed descriptions of the requirements for a product or component. These specifications outline materials, dimensions, tolerances, and other critical parameters that must be met during fabrication and assembly.

Technical Specifications

Machining is a fundamental process in fabrication that involves removing material from a workpiece to achieve the desired shape and size. There are various machining techniques, including milling, turning, drilling, and grinding, each suited to different applications and materials. Machining capabilities are essential for achieving precision and accuracy in fabrication, making them indispensable in modern manufacturing.

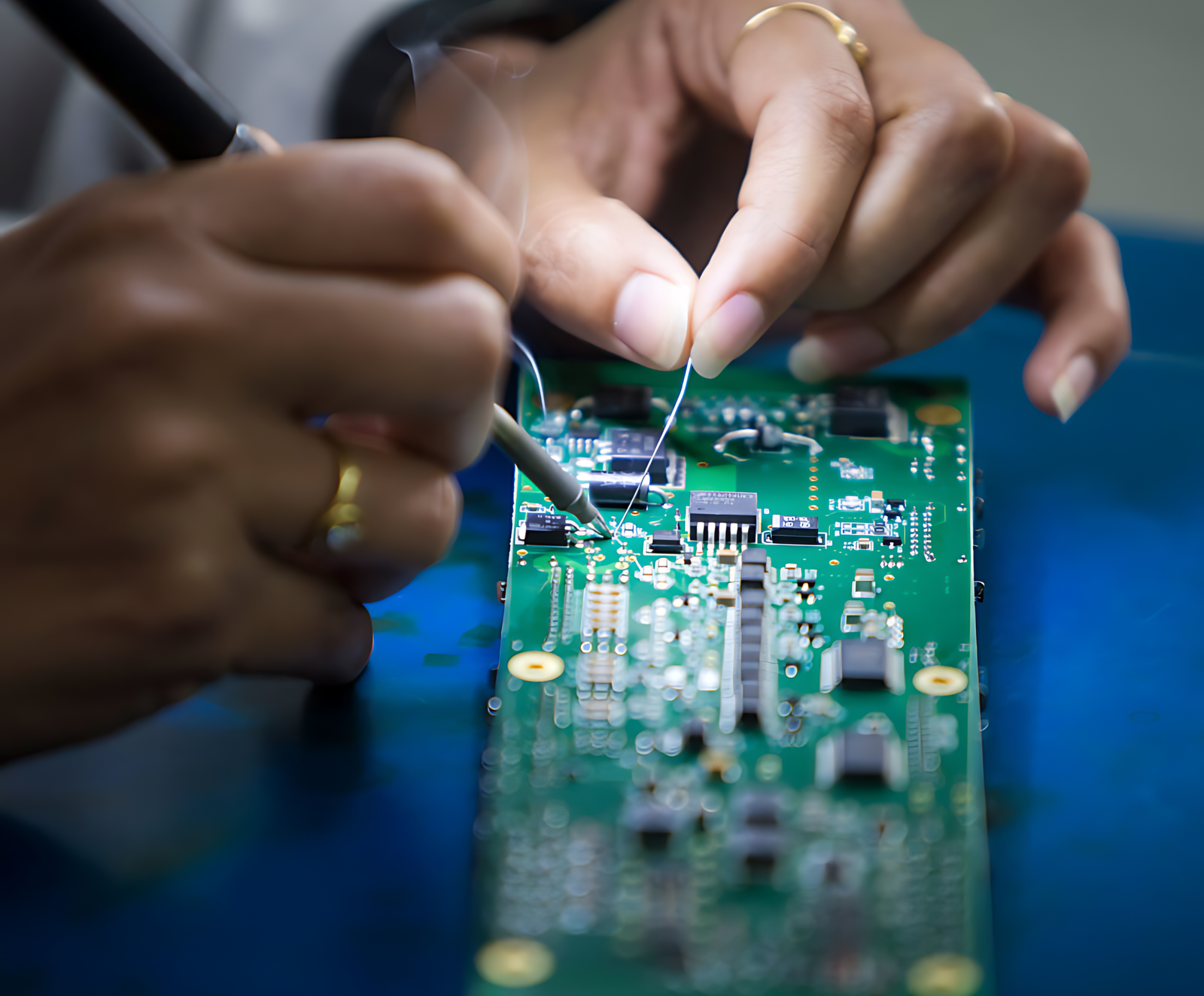

Our team of skilled professionals utilizes a diverse range of joining and finishing techniques to create your desired product. These techniques include:

Welding: We offer various welding processes like TIG welding, MIG welding, and spot welding to join metal components securely.

Riveting: We utilize riveting techniques for permanent or semi-permanent fastening of metal parts.

Adhesives: For specific applications, we employ industrial adhesives to bond different materials.

Finishing: We offer various finishing options like painting, powder coating, and anodizing to enhance aesthetics and part performance.

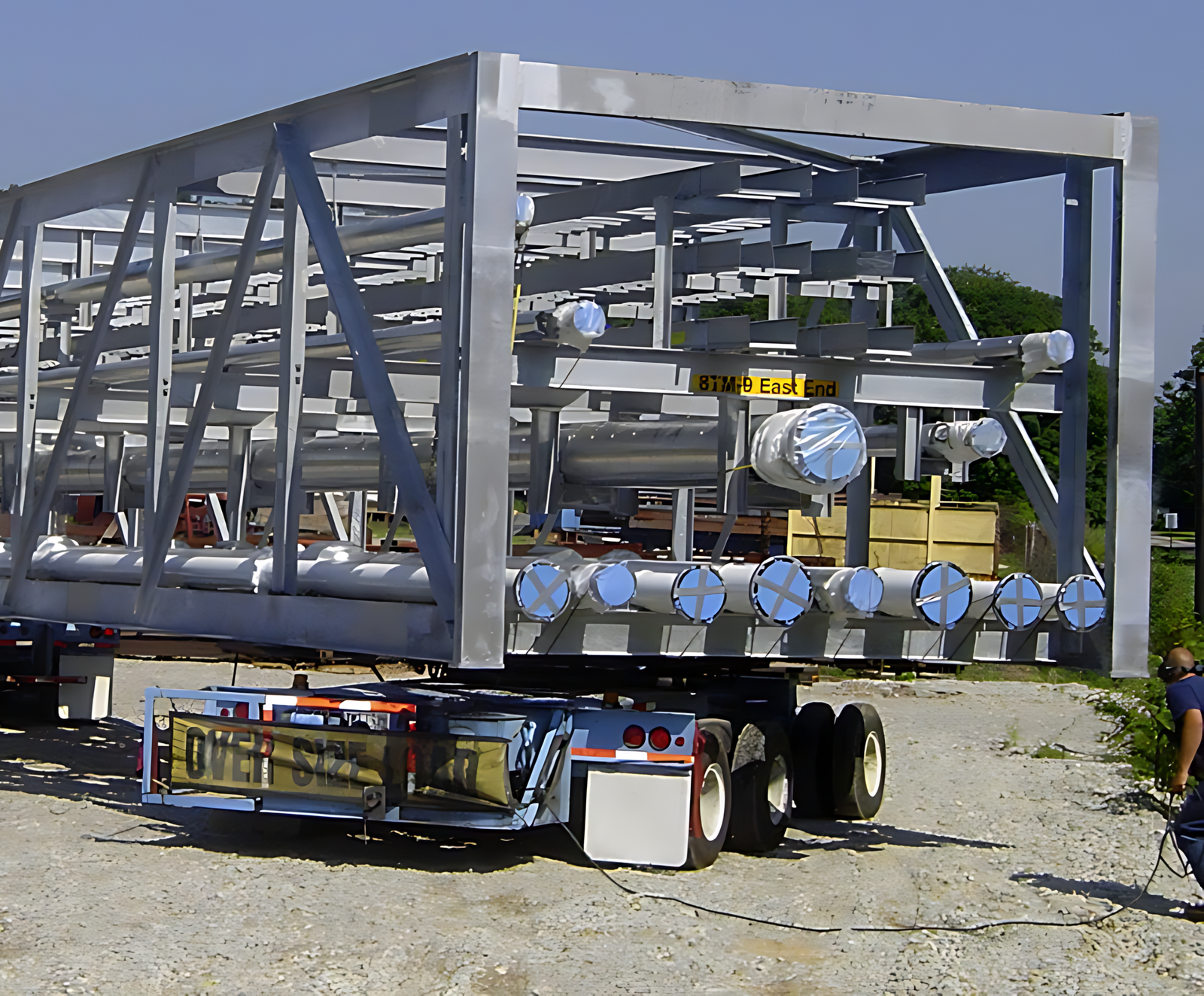

Advancements in technology have revolutionized the field of fabrication, enabling manufacturers to produce complex components with unprecedented speed and precision.

Additive manufacturing, also known as 3D printing, allows for the creation of intricate shapes layer by layer, opening up new possibilities in design and production. Other advanced fabrication technologies, such as laser cutting and waterjet cutting, offer high-speed, high-precision solutions for a wide range of materials and applications.

Our fabrication and assembly expertise encompasses a wide range of materials, including: Metals (steel, aluminum, stainless steel, etc.) Plastics Composites.

Selecting the right material for a specific application requires careful consideration of factors such as strength, weight, corrosion resistance, and thermal conductivity.

We adhere to strict quality control measures throughout the fabrication and assembly process. This includes: Visual inspection of welds and joints for proper quality Dimensional checks to ensure assembled components meet specifications Functionality testing of the final product.

Our advanced machinery and processes guarantee tight tolerances and high repeatability for all your parts.

3+2 axis machining and optimized toolpath programming enable efficient production, reducing lead times.

We can handle intricate designs with confidence, thanks to our advanced 5-axis CNC machining capabilities.

We work with a wide range of materials to suit your specific project requirements.

Our commitment to ISO standards and rigorous inspections

Machining Capabilities

With cutting-edge technology and a compassionate approach, we aim to make your Manufacturing experience comfortable and stress-free

Latest News

- Upper Pivot Project – Case Study August 26, 2025

- Texas Truck Suspension Parts Project – Case Study August 26, 2025

- 🛠️ PROJECT SHOWCASE TEMPLATE – MULTI-PROCESS MANUFACTURING August 26, 2025

- Strike Project – Case Study August 26, 2025

Ph. No. & Address

USA: +1 331-215-4181

India: +91 63 5575 2382