FORGING

FORGING

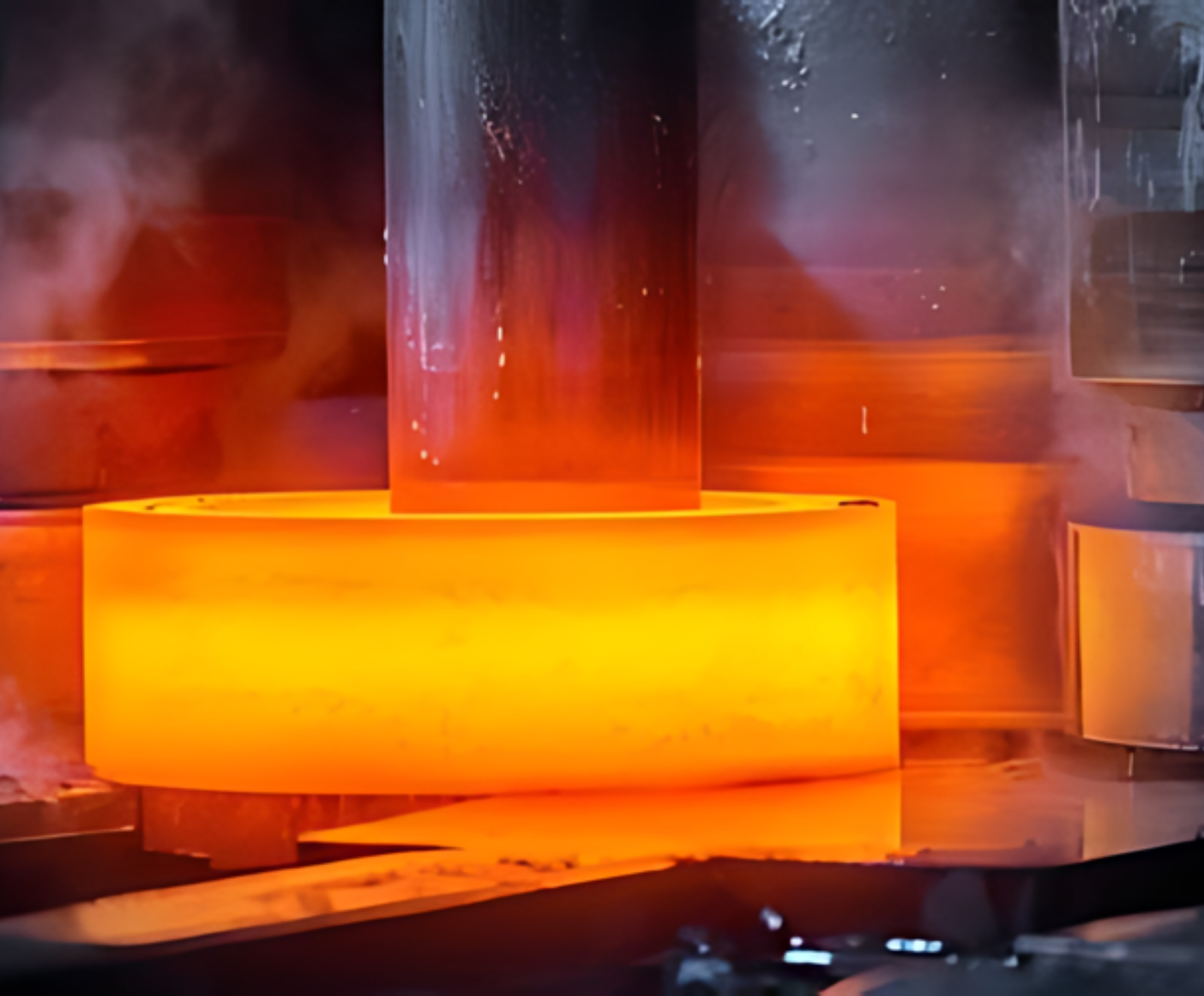

Forging is a manufacturing process that involves shaping metal using localized compressive forces. It’s like sculpting metal, but instead of clay, we’re working with materials like steel, aluminum, or titanium.

Forging is crucial across industries, from automotive to aerospace. It creates strong, durable parts with precise shapes, making it essential for producing components like crankshafts, gears, and connecting rods.

Technical Specifications

We offer two primary forging techniques to suit your needs:

Open-die forging: Suitable for large workpieces and producing simple shapes.

Closed-die forging: Ideal for creating complex near-net-shape components with tight tolerances.

Our forging capabilities are supported by powerful hydraulic presses with a maximum capacity of [mention weight and dimension limits].

Choosing the right material is key. Factors like strength, durability, and temperature resistance play a significant role in determining which metal is best suited for the job.

We can forge a wide range of metals, including:

Steel (various grades)

Aluminum

Brass

Our forging process incorporates rigorous quality control measures to ensure exceptional part integrity. This includes:

Material testing to verify properties

Dimensional checks of forged parts

Ultrasonic testing to detect internal defects

With cutting-edge technology and a compassionate approach, we aim to make your Manufacturing experience comfortable and stress-free

Latest News

- Upper Pivot Project – Case Study August 26, 2025

- Texas Truck Suspension Parts Project – Case Study August 26, 2025

- 🛠️ PROJECT SHOWCASE TEMPLATE – MULTI-PROCESS MANUFACTURING August 26, 2025

- Strike Project – Case Study August 26, 2025

Ph. No. & Address

USA: +1 331-215-4181

India: +91 63 5575 2382