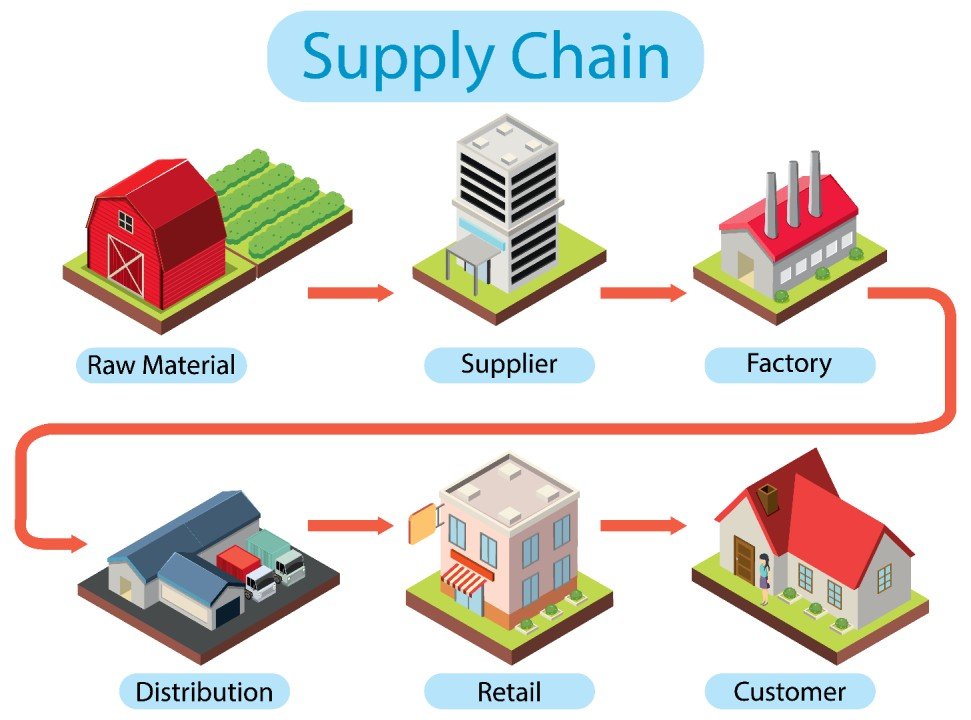

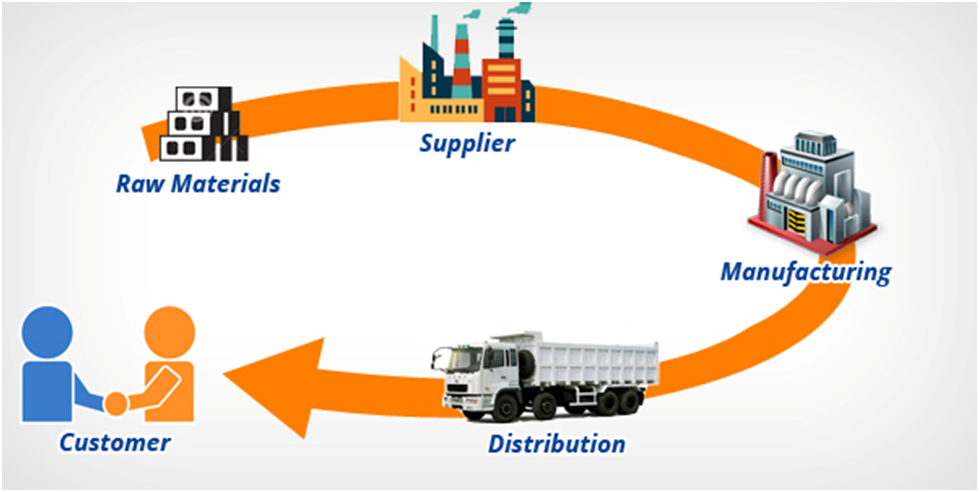

Supply management is one of those terms you hear tossed around in manufacturing, but what does it really mean, and why is it so crucial? If you’ve ever wondered how products go from raw materials to finished goods, supply management plays a huge part in that transformation. Whether you’re running a large production line or a small microfactory, having a robust supply management system is like having the GPS for a road trip. It helps guide everything, ensuring you stay on track, avoid hiccups, and reach your destination on time.

Let’s dive deeper into the role of supply management in manufacturing, its importance, and how microfactories are nailing it with their innovative approach.

Table of Contents

1. What Is Supply Management?

At its core, It is the process of overseeing and optimizing the sourcing, procurement, and logistics of the materials needed to manufacture products. It ensures that the right materials are available at the right time, in the right quantities, and at the right price. Sounds simple, right? But it’s a bit like juggling while riding a bike—there’s a lot going on behind the scenes.

Supply management involves several components, such as:

- Procurement: Finding and buying raw materials.

- Supplier relationship management: Maintaining healthy partnerships with suppliers.

- Logistics: Managing how materials move from one place to another.

- Inventory management: Balancing how much stock to keep on hand to avoid shortages or excess.

2. what is the Importance of Supply Management in Manufacturing

So why is it such a big deal? The reality is, without proper supply management, production lines would come to a screeching halt. Imagine trying to bake a cake and halfway through realizing you don’t have any eggs. That’s exactly what could happen in manufacturing if the supply chain isn’t well-managed.

Some key reasons supply management is critical include:

a. Cost Efficiency

Good supply management helps manufacturers save money. When you’ve got a clear view of your supply chain, you can avoid unnecessary costs, like overpaying for materials or rush shipping.

b. Reducing Downtime

Downtime is the enemy of manufacturing. Every minute a machine isn’t running, money is lost. It ensures materials arrive on time so production doesn’t grind to a halt.

c. Enhancing Quality

A well-managed supply chain doesn’t just focus on quantity but quality too. Consistently sourcing high-quality materials ensures that the end product meets quality standards and customer expectations.

3. What is the Key Components of Effective Supply Management

To truly understand the role of it in manufacturing, it’s essential to break down its key components:

a. Strategic Sourcing

Strategic sourcing is about finding the best suppliers for your needs. This involves more than just finding the cheapest option. You want suppliers who can offer consistent quality, reliability, and value over time.

b. Supplier Relationship Management

Building strong relationships with suppliers can make or break your supply chain. Good relationships lead to better communication, more flexible terms, and sometimes even priority treatment during shortages.

c. Just-in-Time Inventory (JIT)

The inventory system ensures that materials arrive just when they’re needed in the production process. This minimizes the need for storage and reduces waste.

d. Risk Management

A solid supply management system accounts for potential risks, such as natural disasters, geopolitical issues, or supplier bankruptcies. Having a plan B in place ensures your operations continue smoothly even when the unexpected happens.

4. The Role of Technology in Supply Management

In today’s fast-paced world, relying on manual processes for supply management is like using a flip phone in the age of smartphones. Technology is pivotal in modern supply management by streamlining operations and providing real-time insights.

Some key technologies include:

a. Supply Chain Management Software

SCM software helps manufacturers track inventory levels, monitor supplier performance, and streamline the entire procurement process. It provides a bird’s-eye view of the supply chain, allowing for quick decision-making and problem-solving.

b. Artificial Intelligence and Machine Learning

AI and machine learning are transforming how manufacturers manage their supply chains. These technologies can predict demand, optimize inventory levels, and even suggest alternate suppliers in times of crisis.

c. Internet of Things

IoT devices can track the movement of materials in real time, providing manufacturers with up-to-the-minute data on the location and condition of their supplies.

5. Microfactory: Revolutionizing Supply Management

When we think of manufacturing, most of us picture huge factories with assembly lines stretching as far as the eye can see. Enter the microfactory highly automated facility that focuses on producing small batches of products quickly and efficiently.

Microfactories are shaking up the traditional manufacturing model by emphasizing flexibility, cost-efficiency, and sustainability. One area where they’re excelling? You guessed it supply management.

a. Agile Supply Chains

Because microfactory focuses on smaller production runs, they have more agile supply chains. They can quickly switch suppliers or adjust their inventory levels in response to demand changes, giving them a significant advantage in fast-moving industries.

b. Local Sourcing

Many microfactory prioritize local sourcing, reducing the time and cost associated with shipping materials from far-off locations. This also reduces their carbon footprint—making their supply chains not just efficient, but eco-friendly too.

c. Minimal Waste

Microfactory often use just-in-time inventory systems, minimizing waste and ensuring they only order what they need. This is not only cost-effective but also aligns with sustainable manufacturing practices.

6. How Microfactory Are Leading Supply Management

A standout example of a microfactory leading the charge in supply management is Microfactory. This innovative company has fully embraced technology, using AI-driven supply chain software to manage procurement and track inventory.

Microfactory focuses on local suppliers to cut down on shipping costs and times, while their automated systems ensure they only order the exact amount of materials needed for each production run. Their commitment to sustainability and efficiency has positioned them as leaders in the world of supply management.

7. The Challenges of Supply Management in Manufacturing

While they offers many benefits, it’s not without its challenges. Here are a few that manufacturers often face:

a. Supplier Delays

Even with the best supply chain management system, manufacturers can still face delays from suppliers. Natural disasters, transportation issues, or labor strikes can all lead to late deliveries.

b. Quality Control

Sourcing materials from multiple suppliers can lead to inconsistent quality. Maintaining strict quality control measures is essential to ensure that each supplier meets the necessary standards.

c. Rising Costs

Inflation, fuel prices, and global trade tensions can drive up the cost of raw materials, putting pressure on manufacturers to find cost-saving alternatives without sacrificing quality.

8. The Future of Supply Chain Management in Manufacturing

The future of it in manufacturing is exciting, with advancements in technology and sustainability leading the way. Here’s a glimpse into what the future holds:

a. Increased Automation

As AI and machine learning continue to evolve, we can expect even more automated supply chains. From predicting demand to automating procurement, the future of it will be faster and more efficient than ever.

b. Sustainability at the Forefront

Manufacturers are becoming increasingly aware of the need to reduce their environmental impact. Expect to see more emphasis on sustainable sourcing, eco-friendly materials, and reduced waste in the supply chain.

c. Blockchain Technology

Blockchain has the potential to revolutionize supply management by providing complete transparency and traceability in the supply chain. This will help manufacturers ensure ethical sourcing and reduce fraud.

FAQs

What is the role of supply management in manufacturing?

It ensure that materials and components are sourced, stored, and delivered efficiently within a manufacturing process. It optimizes the flow of goods and information, minimizes costs, and ensures production continuity.

Why is inventory management important in manufacturing?

Effective inventory management ensures manufacturers have the right amount of stock to meet production demands without tying up too much capital or risking waste through overstocking. It prevents delays caused by material shortages.

How does supply management affect product quality?

By controlling the sourcing of high-quality materials and closely monitoring suppliers, supply chain management ensures that only the best components enter the production line, reducing defects and improving product quality.

What is sustainable supply management?

Sustainable supply chain management involves sourcing eco-friendly materials, optimizing transportation routes to reduce fuel consumption, and minimizing waste in the supply chain. Companies like Microfactory emphasize sustainability in their operations.

How does Microfactory lead in supply management?

Microfactory excels in real-time inventory tracking, sustainable sourcing, and risk management, while using data-driven approaches to streamline logistics and optimize every aspect of the supply chain.

Conclusion

In the fast-paced world of manufacturing, supply management plays a pivotal role in ensuring that products are made efficiently, cost-effectively, and with consistent quality. From sourcing raw materials to managing supplier relationships, supply management is the backbone of any successful manufacturing operation. And with the rise of microfactory, we’re seeing a new approach to supply management—one that emphasizes agility, local sourcing, and sustainability.

Whether you’re a large factory or a small microfactory, mastering supply management is key to staying competitive in today’s market