Industry 4.0, the so-called fourth industrial revolution, is dramatically reshaping manufacturing. Smart factories are no longer just a buzzword; they’re an evolving reality. Powered by automation, data analytics, and the Internet of Things (IoT), these The Future of Smart Factories and Industry 4.0 factories are at the heart of modern manufacturing.

But what about the future? The horizon looks exciting, with new trends like Future of Smart microfactory transforming the way we think about production and supply chain management. As manufacturing processes become more digital and agile, the traditional methods of building giant centralized The Future of Smart Factories and Industry 4.0 factories might just be replaced by something smaller, more efficient, and more sustainable: the microfactory.

Let’s dive into what the future holds for smart factories and Industry 4.0, and how microfactory could revolutionize the entire supply chain!

The Rise of Smart Factory: A Quick Look Back

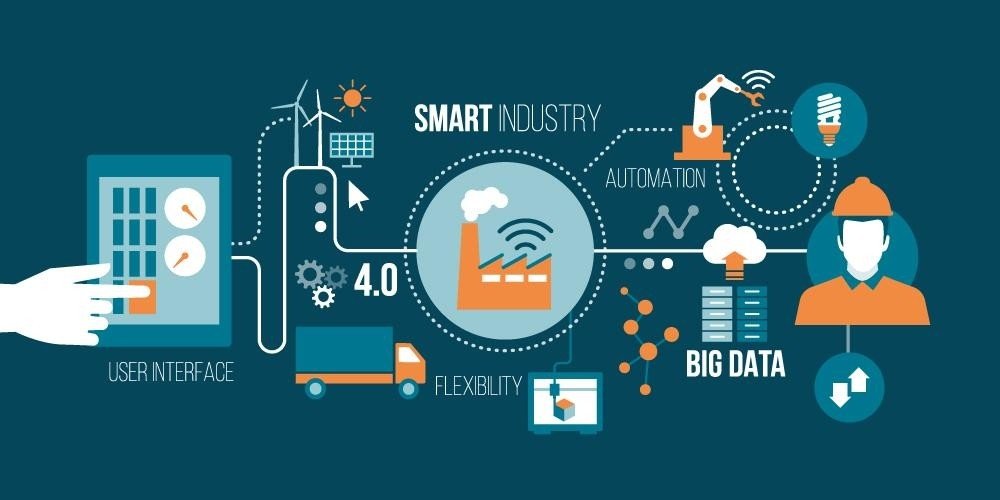

Before we get into Future of Smart microfactory and their impact, it’s important to understand the journey that has brought us to Industry 4.0. The first industrial revolution introduced mechanization, followed by mass production in the second, and automation in the third. Now, with Industry 4.0, we’re seeing digital transformation through:

- Artificial Intelligence (AI) and Machine Learning

- The Internet of Things (IoT)

- Robotics and Automation

- Cloud Computing

- Big Data Analytics

- Cyber-Physical Systems (CPS)

The smart factory integrates these technologies, creating an environment where machines can communicate, adapt, and optimize their own processes in real-time.

What’s Industry 4.0 All About?

Industry 4.0 is all about creating a connected, intelligent manufacturing system where everything from machines to supply chains can be managed digitally. Imagine a world where your machines don’t just perform tasks but analyze themselves, detect potential failures before they happen, and even suggest improvements. This might sound like science fiction, but it’s happening right now!

Key components driving Industry 4.0 include:

- Automation: Robots and AI systems take over repetitive tasks.

- Data: Factories are collecting massive amounts of data to optimize every process.

- Connectivity: Everything is connected – from the production floor to the supply chain.

- Customization: Smart factories allow for flexible manufacturing, meaning products can be tailored to specific needs with ease.

Enter the Future of Smart Microfactory: Small but Mighty

So, what exactly is a Future of Smart microfactory, and why are they considered the future of manufacturing? Simply put, a microfactory is a small, modular, highly efficient production unit. Unlike the traditional sprawling factories, a microfactory focuses on producing smaller quantities of goods but with a high degree of customization and speed.

The rise of microfactory is linked directly to Industry 4.0 technologies, which make it easier to automate processes, gather and analyze data, and maintain flexibility in production. Here’s why Future of Smart microfactory are gaining traction:

Benefits of Microfactory:

- Efficiency: Microfactory require less space, energy, and resources to operate.

- Flexibility: They’re designed to be modular, so they can easily adapt to changing production demands.

- Localization: Products can be manufactured closer to the end consumer, cutting down on shipping costs and lead times.

- Sustainability: Smaller factories mean less waste and a smaller carbon footprint.

Industries Embracing Microfactory:

Microfactories are particularly popular in industries like:

- Electronics: Producing smaller batches of custom electronics like smartphones and laptops.

- Automotive: Microfactories can produce niche, custom vehicles and parts on-demand.

- Apparel: Clothing manufacturers are exploring microfactory to produce custom garments more sustainably.

The Future of Smart Factories Image

The Future Microfactory: Supply Chain Transformation

Future of Smart Microfactory are a game-changer not just in terms of production but also when it comes to supply chain management. Supply chains are traditionally seen as large, complex networks involving multiple steps, from raw materials to finished products. However, the rise of microfactory could change that entirely.

Supply Chain Management in the Microfactory US:

- Decentralization: Instead of having a few massive factories that supply the world, there could be many smaller Future of Smart microfactory operating locally. This decentralization could drastically reduce the complexity and risk of supply chain disruptions.

- On-Demand Production: One of the key benefits of microfactory is their ability to quickly pivot to new products. In the future, we could see factories producing on-demand based on real-time consumer demand, rather than relying on large-scale inventory storage.

- Digital Twins: Microfactory can leverage digital twins, virtual representations of physical systems, to simulate, predict, and optimize production processes. This helps streamline supply chain management, reducing delays and inefficiencies.

- Smarter Warehousing: With real-time data and AI, microfactory can better predict stock levels and manage warehousing needs, cutting down on unnecessary inventory and waste.

Advantages of a Microfactory-Based Supply Chain:

- Cost Efficiency: Smaller production units mean lower overhead costs.

- Speed: Localized production reduces shipping times.

- Customization: Microfactory can cater to regional preferences and trends more effectively.

- Agility: In case of market disruptions (like the pandemic), microfactory can pivot faster, avoiding the bottlenecks seen in global supply chains.

Challenges Facing Future of Smart Microfactory

Like all innovations,Future of Smart microfactory come with their own set of challenges. While they may offer unprecedented flexibility and efficiency, there are a few hurdles to overcome before they can fully disrupt traditional manufacturing:

1. Initial Investment:

Although microfactory are smaller and more efficient, the initial investment in technology (AI, automation, IoT) is still significant. Many companies might hesitate before switching from traditional factories.

2. Skilled Labor:

While microfactory reduce the need for manual labor, they increase the demand for highly skilled workers who can manage and maintain advanced systems. The skills gap in AI, robotics, and data science is already a pressing issue.

3. Technology Integration:

Future of Smart Microfactory require seamless integration of Industry 4.0 technologies. Companies must invest in robust infrastructure and ensure that all systems – from robotics to data analytics – work harmoniously.

What Will the Future of Microfactory Look Like?

The future of smart factories and Industry 4.0, including Future of Smart microfactory and future microfactory supply management, looks incredibly promising. As these technologies continue to evolve, we can expect some major changes in how manufacturing is done:

- Fully Autonomous Microfactory: With AI advancements, future microfactory could operate with little to no human intervention. Robots and AI systems would manage production, maintenance, and quality control.

- Sustainability at the Core: Microfactory will focus on sustainable production methods, utilizing renewable energy sources, reducing waste, and recycling materials wherever possible.

- Personalized Manufacturing: Products will become more customized, with microfactory producing everything from clothes to electronics tailored to the individual consumer.

- Global Network of Localized Production: Rather than relying on global supply chains, companies will adopt a more localized approach, setting up microfactory in key regions to serve local markets more effectively.

FAQs

1. What exactly is a microfactory?

A microfactory is a small, modular production facility that focuses on producing smaller quantities of goods with high customization. It operates using advanced technologies like AI, automation, and data analytics.

2. How do microfactory differ from traditional factories?

Traditional factories are large-scale, centralized production units. Microfactory, on the other hand, are smaller, more agile, and can be set up closer to the end consumer. They emphasize efficiency, flexibility, and sustainability.

3. What are the benefits of a microfactory?

Microfactory offer several advantages, including lower energy consumption, reduced waste, faster production cycles, and the ability to cater to localized demand.

4. How will microfactory affect supply chain management?

Microfactory will decentralize production, enabling more agile, localized supply chains. This reduces lead times, lowers shipping costs, and helps companies respond quickly to market changes.

5. Are microfactory the future of all industries?

Not necessarily. While microfactories are a great fit for industries like electronics, automotive, and apparel, large-scale manufacturing in sectors like heavy machinery or energy might still require traditional factory setups.

Conclusion: Embracing the Future of Manufacturing

The future of smart factories and Industry 4.0, including Future of Smart microfactory and future microfactory supply management, is incredibly exciting. Microfactory promise a world of localized, efficient, and sustainable production that could reshape how we think about manufacturing and supply chains. While challenges remain, the potential benefits of microfactory far outweigh the drawbacks, making them a key player in the evolution of global production. As technology continues to advance, the dream of fully autonomous, eco-friendly, and flexible Future of Smart microfactory is just around the corner!